ABSTRACT

Pursuant to the goals of sustainable development, and in line with current energy needs, it is increasingly necessary to create more energy-efficient processes, and reduce their carbon footprint. New energy-efficient technologies for heavy oil recovery must be developed, such as hybrid technologies, where some additives are used for steam injection processes. One of the hybrid technologies with good potential for energy-efficient heavy oil recovery is cyclic steam injection with solvents enhanced with nanocatalysts (HYB-SEN), which could also generate oil upgrading by pseudo-aquathermolysis reactions. According to the above, this research focused on evaluating the impact on the reduction of greenhouse gases of the hybrid steam technology with naphtha-based nanofluids concerning the conventional cyclic steam injection (CSS).

For this purpose, a simulation model for conventional cyclic steam stimulation (CSS) called the CSS baseline was created, including the pseudo-aquathermolysis reaction and the reaction kinetics based on experimental tests such as thermogravimetric analysis (TGA), analysis of gases and fluids after coreflooding tests in the presence and absence of nanocatalysts, physicochemical characterization tests of crude oil, naphtha, among others, as well as fluid properties software. On the other hand, the reduction in the production of greenhouse gases by hybrid technology concerning the CSS baseline was calculated. The impact of the hybrid technology on the injection scenarios was determined through the proposed environmental indicators like energy efficiency, reduction of Basic Sediment and Water (BSW), and reduction of carbon footprint reflected in lower carbon -intensity, among others, by numerical simulation.

The results of the hybrid technology with nanocatalysts simulation showed an increase in oil recovery of an additional 3756.5 Bbl of crude oil compared to the conventional technique and a reduction greater than 18% for the CO2 production compared to conventional cyclical steam injection. Further, the environmental impact analysis of the scenario concerning the baseline was evaluated, finding a positive impact on energy efficiency improvement, reduction of BSW, and reduction of carbon footprint reflected in lower carbon-intensity, among others. Additionally, hybrid technology results in an additional benefit with the use of raw materials such as naphtha in crude oil transportation, used at the field, which implies a reduction in their subsequent use due to the improvement of crude oil properties.

The foregoing indicates that hybrid steam technology with naphtha-based nanomaterials not only generates positive impacts on oil recovery compared to the conventional technique, but also has a positive effect by enhancing energy efficiency and reducing carbon footprint.

KEYWORDS:

Hybrid technology; nanocatalyst; energy efficiency; environmental indicators; cyclic steam stimulation

RESUMEN

De acuerdo con las metas de desarrollo sostenible y alineado con las necesidades energéticas actuales cada vez se hace más necesario generar procesos más eficientes energéticamente y reducir la huella de carbono asociada al proceso. Debido a esta necesidad, se requiere generar tecnologías más eficientes para la recuperación de petróleo basadas en las ya existentes para crudo pesado como lo es la inyección de vapor, a raíz de esto surgen las denominadas tecnologías híbridas. Una de las tecnologías híbridas que podría tener un buen potencial en la recuperación eficiente de crudos pesados es la inyección cíclica de vapor con solventes mejorados con nanocatalizadores, el cual además podría generar mejoramiento de crudos pesados en procesos de recobro térmico, específicamente en reacciones de acuatermólisis ocurridas en procesos de inyección de vapor.

Debido a lo anterior, este trabajo se centró en la estimación del impacto en la reducción de gases de efecto invernadero de la tecnología híbrida de vapor con nanofluidos base nafta respecto a la tecnología convencional de inyección cíclica de vapor (CSS). Para este fin se generó un modelo de simulación para la inyección cíclica de vapor (CSS) convencional denominada caso base en la que se incluyó la reacción de acuatermólisis y la cinética de la reacción los cuales se basan en pruebas experimentales como análisis termogravimétrico (TGA), análisis de gases y fluidos posterior al desplazamiento en presencia y ausencia de nanocatalizadores, pruebas de caracterización fisicoquímica de crudo, nafta entre otros, así como un software de propiedades de los fluidos. Por otro lado, se determinaron los gases de efecto invernadero de la tecnología híbrida y se evaluó su reducción respecto al caso base. De acuerdo con los indicadores ambientales propuestos se evaluó el impacto ambiental de la tecnología híbrida con el escenario de inyección propuesto y desarrollado mediante simulación numérica.

Los resultados de la simulación de la tecnología híbrida con nanocatalizadores mostraron un incremento de recobro para este caso de 3756.5 Bbl adicionales de crudo respecto a la técnica convencional y una reducción superior al 18% para la producción de CO2 respecto a la inyección cíclica de vapor convencional. Por otro lado, se realizó el análisis de impacto ambiental del escenario evaluado respecto al caso base encontrándose un impacto positivo respecto a mejora de la eficiencia energética, reducción de BSW, reducción de huella de carbono reflejado en una menor carbono-intensidad entre otros. Adicionalmente, la tecnología híbrida presenta un beneficio adicional con el uso de materias primas como la nafta en transporte de crudo, empleándolas en yacimiento, lo que implica una reducción en su uso posterior debido a la mejora de las propiedades del crudo.

Lo anterior, indica que la tecnología híbrida de vapor con nanofluidos base nafta no solo genera impactos positivos en productividad, es decir mayor recobro respecto a la técnica convencional, sino que además impacta positivamente en la mejora de la eficiencia energética y la reducción de huella de carbono.

PALABRAS CLAVE:

Tecnología híbrida; nanocatalizador; eficiencia energética; indicadores ambientales; inyección cíclica de vapor

INTRODUCTION

Approximately 45% of the current production in Colombia corresponds to heavy crudes (Bera & Babadagli, 2015Bera, A., & Babadagli, T. (2015). Status of electromagnetic heating for enhanced heavy oil/bitumen recovery and future prospects: a review. Applied Energy, 151, 206-226 https://doi.org/10.1016/j.apenergy.2015.04.031

https://doi.org/10.1016/j.apenergy.2015....

), (Franco et al., 2008Franco, C Flórez, A., & Ochoa, M. (2008). Análisis de la cadena de suministros de biocombustibles en Colombia. Revista de Dinámica de Sistemas, 4(2), 109-133. https://www.researchgate.net/profile/Camila-Ochoa/publication/263816420_Analisis_de_la_cadena_de_suministro_de_biocombustibles_en_Colombia/ links/57d04b7108ae6399a389d710/Analisis-de-la-cadena-de-suministro-de-biocombustibles-en-Colombia.pdf

https://www.researchgate.net/profile/Cam...

). The extraction of this type of crude is carried out mostly through thermal recovery methods in which catalytic processes may contribute to the recovery process, such as thermal cracking, ( Montoya et al., 2016Montoya, T., Argel, B. L., Nassar, N. N., Franco, C . A. , & Cortés, F. B. (2016). Kinetics and mechanisms of the catalytic thermal cracking of asphaltenes adsorbed on supported nanoparticles. Petroleum Science, 13, 561-571. https://doi.org/10.1007/s12182-016-0100-y

https://doi.org/10.1007/s12182-016-0100-...

) (Husein & Alkhaldi, 2014Husein, M. M., & Alkhaldi, S. J. (2014). In situ preparation of alumina nanoparticles in heavy oil and their thermal cracking performance. Energy and Fuels, 28, 6563-6569. https://doi.org/10.1021/ef5012963

https://doi.org/10.1021/ef5012963...

), aquathermolysis ( Yi et al., 2018Yi, S., Babadagli, T., & Andy Li, H. (2018). Use of nickel nanoparticles for promoting aquathermolysis reaction during cyclic steam stimulation. SPE Journal, 23(01), 145-156. https://doi.org/10.2118/186102-PA

https://doi.org/10.2118/186102-PA...

), hydrocracking, (Kaminski et al., 2018Kaminski, T., Anis, S. F., Husein, M. M., & Hashaikeh, R. (2018). Hydrocracking of Athabasca VR Using NiO-WO3 Zeolite-Based Catalysts. Energy and Fuels, 32, 2224-2233. https://doi.org/10.1021/acs.energyfuels.7b03754

https://doi.org/10.1021/acs.energyfuels....

) oxidation (Franco et al., 2015Nassar, N. N. , Franco, C . A. , Montoya, T. , Cortés, F. B. , & Hassan, A. (2015). Effect of oxide support on Ni-Pd bimetallic nanocatalysts for steam gasification of n-C7 asphaltenes. Fuel, 156, 110-120. https://doi.org/10.1016/j.fuel.2015.04.031

https://doi.org/10.1016/j.fuel.2015.04.0...

), (Tang et al., 2017Tang, X. D., Liang, G. J., Li, J. J., Wei, Y. T., & Dang, T. (2017). Catalytic effect of in-situ preparation of copper oxide nanoparticles on the heavy oil low-temperature oxidation process in air injection recovery. Petroleum Science and Technology, 35(13), 1321-1326. https://doi.org/10.1080/10916466.2017.1318145

https://doi.org/10.1080/10916466.2017.13...

), pyrolysis (Amrollahi et al., (2018)Amrollahi Biyouki, A., Hosseinpour, N., & Nassar, N. N. (2018). Pyrolysis and oxidation of asphaltene-born coke-like residue formed onto in situ prepared NiO nanoparticles toward advanced in situ combustion enhanced oil recovery processes. Energy & fuels, 32(4), 5033-5044. https://doi.org/10.1021/acs.energyfuels.8b00638

https://doi.org/10.1021/acs.energyfuels....

; (Biyouki et al., 2017Biyouki, A. A., Hosseinpour, N., Bahramian, A., & Vatani, A. (2017). In-situ upgrading of reservoir oils by in-situ preparation of NiO nanoparticles in thermal enhanced oil recovery processes. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 520, 289-300. https://doi.org/10.1016/j.colsurfa.2017.01.089

https://doi.org/10.1016/j.colsurfa.2017....

), and steam gasification, ( Nassar et al 2015Nassar, N. N. , Franco, C . A. , Montoya, T. , Cortés, F. B. , & Hassan, A. (2015). Effect of oxide support on Ni-Pd bimetallic nanocatalysts for steam gasification of n-C7 asphaltenes. Fuel, 156, 110-120. https://doi.org/10.1016/j.fuel.2015.04.031

https://doi.org/10.1016/j.fuel.2015.04.0...

); ( Nassar et al., 2013Hashemi, R., Nassar, N. N., & Pereira Almao, P. (2013). Enhanced heavy oil recovery by in situ prepared ultradispersed multimetallic nanoparticles: A study of hot fluid flooding for Athabasca bitumen recovery. Energy & Fuels, 27, 2194-2201. https://doi.org/10.1021/ef3020537

https://doi.org/10.1021/ef3020537...

), translating into oil upgrading (Shah et al., 2010Shah, A., Fishwick, R., Wood, J., Leeke, G., Rigby, S., & Greaves, M. (2010). A review of novel techniques for heavy oil and bitumen extraction and upgrading. Energy & Environmental Science, 3(6), 700-714. https://doi.org/10.1039/b918960b

https://doi.org/10.1039/b918960b...

).

One of the most widely used techniques in heavy crude oil recovery processes is steam injection, which can be improved with nanotechnology to favor the aquathermolysis process by using nanocatalysts, thus leading to substantial improvement of crude oil in the reservoir, in addition to reducing energy consumption and generating less impact on the environment, with a higher associated recovery factor. The most widely used nanoparticles in this process are metallic and metallic oxides used in asphaltene adsorption and catalytic activation (Hamedi Shokrlu & Babadagli, 2013Hamedi Shokrlu, Y., & Babadagli, T. (2013). In-Situ Upgrading of Heavy Oil/Bitumen During Steam Injection by Use of Metal Nanoparticles: A Study on In-Situ Catalysis and Catalyst Transportation. SPE Res Eval & Eng,, 16(3), 333-344. https://doi.org/10.2118/146661-PA

https://doi.org/10.2118/146661-PA...

). Its mechanism of action consists in reducing the operating temperature of asphaltenes reaction, effective activation energy, and operation of large hydrocarbon chains in lighter fractions with lower molecular weight, which implies a reduction in viscosity and improvement of mobility in the production of extra heavy crude, (Iskandar et al., 2016Iskandar, F., Dwinanto, E., Abdullah, M., & Muraza, O. (2016). Viscosity reduction of heavy oil using nanocatalyst in aquathermolysis reaction. KONA Powder and Particle Journal, 33, 3-16. https://doi.org/10.14356/kona.2016005

https://doi.org/10.14356/kona.2016005...

); (Hashemi et al., 2013Hashemi, R., Nassar, N. N., & Pereira Almao, P. (2013). Enhanced heavy oil recovery by in situ prepared ultradispersed multimetallic nanoparticles: A study of hot fluid flooding for Athabasca bitumen recovery. Energy & Fuels, 27, 2194-2201. https://doi.org/10.1021/ef3020537

https://doi.org/10.1021/ef3020537...

).

However, one of the challenges of using nanocatalysts in cyclic steam stimulation (CSS) is the mechanism to efficiently transport the nanomaterials to the reservoir and contact the oil. Therefore, in previous works, a new hybrid technology called Hyb - SEN (Hybrid Solvent Enhanced Nanoparticles) is proposed (García-Duarte et al., 2024), which could improve the contact between oil and nanoparticles and leverage on the use of solvents such as naphtha.

Notably, out of the 11 million tons of CO2 produced by the oil industry in the country, 53% corresponds to oil production, and 47% to oil refining. Hence, and in addition to the current climate change, the carbon footprint reduction is an important challenge, which is expected to be achieved through the use of hybrid technologies that contribute to improve energy efficiency and reduce the amount of carbon dioxide emitted to the atmosphere.

Hence, this paper presents an estimation of the impact on the reduction of greenhouse gases of novel hybrid steam technology with naphtha-based nanofluids compared to conventional cyclical steam injection (CSS) and cyclical steam injection with naphtha technology. This estimation is based on a representative numerical model of the field under study and the experimental results obtained on the nanofluid selected for the hybrid technology of steam + improved solvent as fluid-fluid interaction, static tests in a batch reactor, kinetic tests using Thermogravimetric Analysis (TGA), and analysis of effluents from dynamic tests.

Furthermore, the simulation methodology had an innovative approach in the way the kinetic parameters with the action of the nanocatalysts are calculated by the Friedman isoconversional method (Friedman, 1964Friedman, H. L. (1964). Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. Journal of Polymer Science Part C: Polymer Symposia, 6(1), 183-195. https://doi.org/10.1002/polc.5070060121

https://doi.org/10.1002/polc.5070060121...

) from the results of the thermogravimetric analysis (Becerra Cardenas, 2014Cárdenas, J. A. B. (2014). Modelo cineticopara determinar parametros cineticos de lapirolisis de la cascarilla de café (Doctoral dissertation, Uniandes). https://repositorio.uniandes.edu.co/bitstreams/97dbd428-b767-4d94-8ffd-81baa2d79108/download

https://repositorio.uniandes.edu.co/bits...

), which allowed testing its application in reactions associated with steam recovery processes such as aquathermolysis. Likewise, in the reaction model proposed by the Hyne model (Hyne, 1986Hyne, J. B. (1986). Aquathermolysis: a synopsis of work on the chemical reaction between water (steam) and heavy oil sands during simulated steam stimulation. https://openlibrary.org/books/OL19361916M/Aquathermolysis

https://openlibrary.org/books/OL19361916...

), stoichiometry was calculated from the batch reactor test and the calculation of the reaction enthalpy. To this end, two scenarios were created, one corresponding to the base case with gas generation by a pseudo-aquathermolysis reaction (based on aquathermolysis reaction excluding H2S that was not detected in the experiments conducted), and the hybrid technology with a steam injection rate equal to the base case.

2 EXPERIMENTAL DEVELOPMENT

For the design of the scheme injection of the hybrid CSS + Naphtha-based NanofLuids technology that allows estimating the impact on the production of greenhouse gases, an implicit numerical model representative of the field under study was developed. Fluid and kinetic parameters were included to generate a representative model for the hybrid technology of CSS + Solvents Enhanced with Nanoparticles (Hyb-SEN) with the use of reservoirsimulators, based on experimental results and fluid modelling software to determine reaction enthalpy and other properties of the fluids involved in the reaction from the PVT behavior modelling.

The main experimental tests carried out to determine the kinetics of the reaction are static tests of catalytic decomposition by TGA of the asphaltene fraction, which were carried out in a TGA Q50 equipment (TA Instruments, Inc, New Castle, DE), with a ramp heating at 10°C/ min from 25°C to 600°C, thermal conductivity performed using a TEMPOS thermal properties analyzer in accordance with ASTM 5334 and IEEE 442 and gas selectivity tests subsequent to coreflooding experiments in the presence and absence of nanoparticles at reservoir conditions. The simulation methodology used is described below:

SIMULATION MODEL

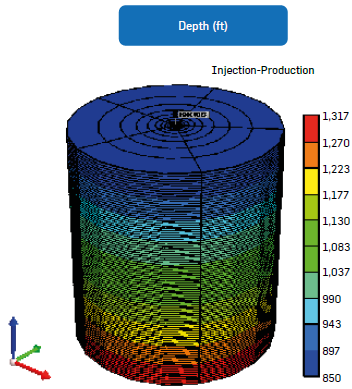

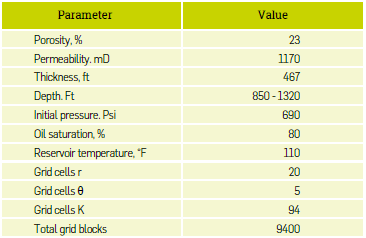

A single well simulation model was created based on the main properties from the reservoir candidate to implement the HYB SEN hybrid technology. Figure 1 shows the 3D representation of the radial model used in this research. Additionally, table 1 references the main parameters related to petrophysical properties and grid size of the numerical model.

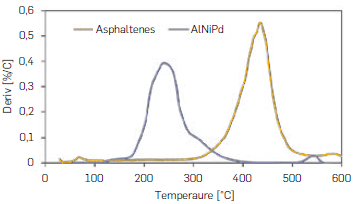

To estimate the greenhouse gases for the baseline, the pseudo-aquathermolysis reaction and its kinetic parameters were ncluded, which were determined from experimental tests such as high-pressure thermogravimetric analysis (TGA), reactor tests isoconversional, and gas spectrometry of the reaction products, which were also performed for crude in the presence of the nanocatalysts selected for the hybrid technology called AINiPd.

The kinetic parameters were estimated from the results of the thermogravimetric tests using Friedman's isoconversional method (Pretell et al., 2020Pretell, V., Ubillas, C., Ruiz, C., Rodriguez, J., & Ramos, W. (2020). Evaluación de los Parámetros Cinéticos por Análisis Termogravimétrico del Esquisto en la Formación Muerto, Talara-Perú. LACCEI Inc. https://www.academia.edu/92509830/Evaluaci%C3%B3n_de_los_Par%C3%A1metros_Cin%C3%A9ticos_por_An%C3%A1lisis_Termogravim%C3%A9trico_del_Esquisto_en_la_Formaci%C3%B3n_Muerto_Talara_Per%C3%BA

https://www.academia.edu/92509830/Evalua...

) as observed in previous work reported by Ruiz-Cañas et al., 2023García-Duarte, H. A., Ruiz-Cañas, M. C., & Pérez-Romero, R. A. (2023). Innovative Experimental Design for the Evaluation of Nanofluid - Based Solvent as a Hybrid Technology for Optimizing Cyclic Steam Stimulation Applications. Energies, 16, 373. https://doi.org/10.3390/en16010373

https://doi.org/10.3390/en16010373...

. The catalytic effect of the nanomaterial's presence on the reactions that occur in the test evaluation range (25 -600°C) should be highlighted.

High-pressure TGA for asphaltene in the absence and presence of the core - shell nanoparticles based on alumina (76 nm).

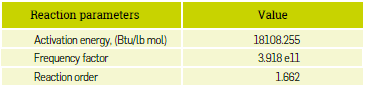

The presence of nanocatalysts generated a reduction in the activation energy concerning the reaction with asphaltenes alone, which indicates that the selected nanomaterial is indeed able to catalyze the thermal decomposition reaction of asphaltenes and reduce the amount of energy required.

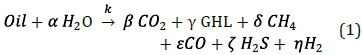

In addition, in the presence of steam, aquathermolysis reactions occur, which mainly form gaseous components such as carbon dioxide, carbon monoxide, and hydrogen sulfide, among others. The reaction that has been modeled by Hyne (Hyne, 1986Hyne, J. B. (1986). Aquathermolysis: a synopsis of work on the chemical reaction between water (steam) and heavy oil sands during simulated steam stimulation. https://openlibrary.org/books/OL19361916M/Aquathermolysis

https://openlibrary.org/books/OL19361916...

), shown in Equation 1, stands out.

Equation 1. Hyne's reaction model.

Where GHL represents light gaseous hydrocarbons and, H2O: water, CO2: carbon dioxide, CH4: methane, CO: carbon monoxide, H2S: hydrogen sulfide and H2: hydrogen.

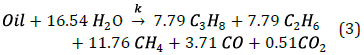

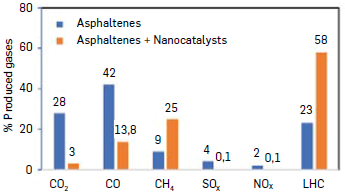

To estimate the stoichiometry of the reaction, the results of mass spectrometry of the TGA with steam test of the asphaltene fraction of crude oil in the presence of nanocatalysts were analyzed (Figure 3), and the fractions obtained according to the molecular weight of each compound produced allow to determine the molar composition of the components in the reaction, and thus determine the stoichiometry of the pseudo-aquathermolysis reaction for this case.

Distribution of the selectivity of gases produced by the reaction for asphaltene in the absence and presence of the nanocatalysts.

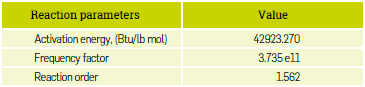

There is a signficant decrease in gases such as COx, NOx, and SOx compared to the pseudo-aquathermolysis reaction not involving nanocatalysts. It is worth noting that the Hyne model accounts for H2S as a by-product of the sulfur compounds in crude oil. However, since the amount of H2S produced was small and could not be detected in the chromatography, the reaction was normalized to exclude H2S as a product. Despite this adjustment, the presence of nanocatalysts resulted in a reduction in the composition of SOX and NOX produced. The kinetic parameters for crude oil are shown in Table 2 based on the results obtained.

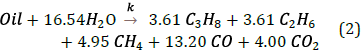

In addition, the conventional cyclic steam injection reaction model (Equation 2) suggests the generation of light compounds.

Equation 2. Modified pseudo-aquathermolysis reaction model for conventional CSS.

In general, there are three phenomena associated to the HYB -SEN scenario: The first one involves the functionalized metallic nanoparticles that act as a catalyst for the pseudo-aquathermolysis reaction, the second one is the co-dilution effect due to the presence of the carrier solvent (naphtha) in the process, and the third one is the upgrading of crude, which leads to a compositional change of the initial crude oil. To model these phenomena, it was necessary to include activation energy at the temperature at which thermal decomposition occurs.

Kinetic parameters for the pseudo-aquathermolysis reaction in the presence of nanocatalysts.

Next, a chemical reaction (Table 3) is proposed where the original oil of the simulation model reacts with water, generating combustion gases and light hydrocarbons.

Equation 3. Modified pseudo-aquathermolysis reaction model in the presence of nanocatalysts.

The reaction and its kinetics are included in the numerical model. The mass balance error is 10-5, which is accurate for generating the reaction.

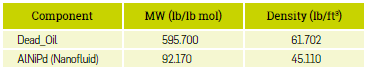

The base fluid model has three components: dead oil, gas in solution, and water. Experimental tests carried out on the crude under study allowed the determination of crude oil average molecular weight and density of naphtha, among others. Table 4 shows the physicochemical properties of the components included.

EVALUATION OF NANOFLUIDS INJECTION SCENARIOS

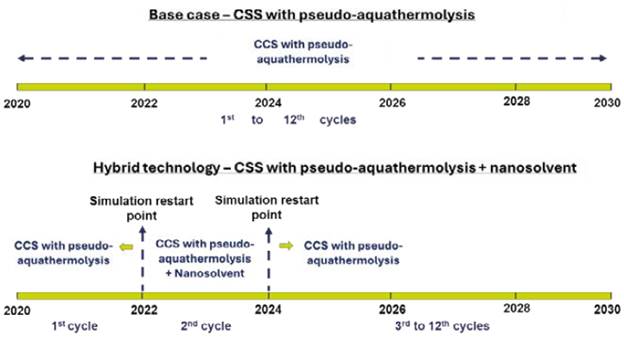

To determine the impact on the reduction of greenhouse gases of the hybrid steam technology with naphtha-based nanofluids and the cyclical injection of conventional steam in the evaluation window of 10 years (2020 - 2030), the following scenarios were created:

CSS base with pseudo-aquathermolysis reaction (12 cycles).

Cyclic injection of steam + solvent (in the second cycle).

Cyclic injection of steam + solvent enhanced with nanofluid (in the second cycle).

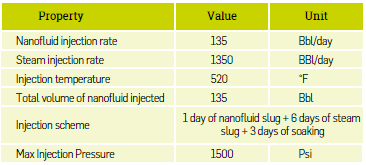

In general, the injection scheme for the base case of cyclic steam injection is as follows: primary production is carried out for three months in the well; then, steam is injected at a constant rate of 1350 bbl/d for six days, with a steam quality of 60% and an njection temperature of 520°F, followed by three days of soaking and then the well is opened for production until it reaches the primary production rate, at which time a new production cycle is started. It should be noted that the model has an injection pressure restriction of 1500 psi, which Is the maximum pressure allowed to avoid possible fracturing of the reservoir.

On the other hand, the nanofluid batch Injection rate was calculated concerning the estimated daily steam injection rate in the base case, 1350 bbl/day, with a 10% ratio that is, 135 bbl/day. It hould be mentioned that the amount of steam Injected was the same as the base case, 8100 barrels in each cycle, 60% steam quality, pressure, and temperature conditions equal to those of the base case, and the same soaking time. Table 5 shows the injection-production conditions for the hybrid technology.

Furthermore, the simulation of nanofluid Injection scenarios Included the keyword "restart" twice: one prior to and the other following its Integration In the second cycle of CCS. The primary Influence is associated with pseudo-aquathermolysis. In the Initial cycle of CCS, a pseudo-aquathermolysis reaction occurs without nanofluid, while in the second cycle, it involves a reaction with nanofluid. Subsequently from the third cycle onward, the pseudo-aquathermolysis reaction without nanofluid is established again (Figure 4).

It should be noted that nanofluid Injection scenarios were created in the second injection cycle as it was the most favorable one for the hybrid CSS + nanofluid technology. In addition, special variables were monitored for analyzing the occurrence of the pseudo-aquathermolysis reaction In the presence of steam and the production of resulting gases.

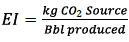

ENVIRONMENTAL INDICATORS

The proposed environmental Indicators calculations depend on the production of C02, which is a function of the origin, and the energy source of the steam generator used for the process. In general, process carbon footprint calculation Is based on ISO 14040 - 44, ISO 14064, and IPCC 2006 standards.

Also, C02 capture is mainly performed with amines and can cost approximately USD 115/ton C02, (Dzlejarski et al., 2023), which could affect the economics of recovery projects. In addition, steam Injection processes generate a signficant amount of C02; It Is in the order of 100 kg of C02/bbl, in contrast to methods such as polymer Injection which generate less than 12 kg of C02/bbl of oil, (Farajzadeh et al. 2022Farajzadeh, R., Glasbergen, G., Karpan, V., Mjeni, R., Boersma, D., Eftekhari, A., . . . Bruining, J. (2022). Improved oil recovery techniques and their role in energy efficiency and reducing CO2 footprint of oil poduction. Journal of Cleaner Production, 369, 133308. https://doi.org/10.1016/j.jclepro.2022.133308

https://doi.org/10.1016/j.jclepro.2022.1...

) mainly due to the combustion produced in steam generators. Therefore, and based on the analysis of the process, the following environmental Indicators are proposed:

Reduction of BSW: The water cut Is related to energy efficiency since the lower the BSW In the field, the lower the energy required by the pump and, therefore, the cost of water treatment is reduced, as well as energy consumption.

Carbon - intensity index: Given by the amount of CO2 produced (surface + reservoir) divided by oil production, that is:

Reduction of emissions: ton CO2/year.

Reduction of required steam rate/oil production.

3 RESULTS ANALYSIS

The results of the scenarios created consist of two parts: initially, evaluations of the pseudo-aquathermolysis reaction are carried out in the base scenarios, followed later by the forecast of the gas production with the hybrid technology. The results obtained are outlined below.

EVALUATION OF THE PSEUDO-AQUATERMOLYSIS REACTION IN STEAM INJECTION PROCESSES

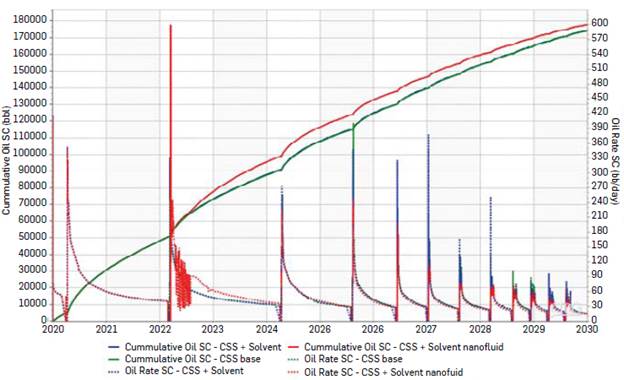

Figure 5 shows the oil production results and daily oil production rates for the CSS baseline, CSS + Solvent and CSS + Hyb-SEN technology.

Cumulative oil and oil production rate, Hybrid Technology nanocatalyst, base case of steam injection and solvent (2020 - 2030).

The incremental recovery obtained by hybrid CSS + Hyb-SEN technology implementation in the evaluation period (2020 to 2030) is 3756.46 bbl compared to the conventional CSS base (Figure 6).

Cumulative oil and oil production rate, Hybrid Technology nanocatalysts, base case of steam injection and solvent (2020 - 2030).

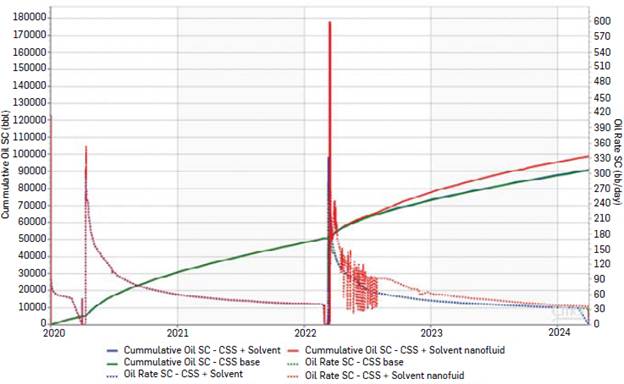

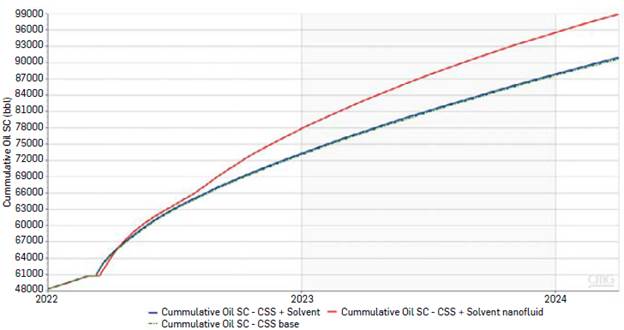

Analyzing the 2020 to 2024 period, which includes the second cycle where the hybrid CSS + Hyb-SEN technology is applied, the incremental oil recovery compared to the CCS base case is 8256.72 bbl (Figure 7). It is worth noting that the CSS + solvent has a very low cumulative oil increment (236 bbl), which is not evident in the figure.

Cumulative oil - 2nd cycle, Hybrid Technology nanocatalysts, base case of steam injection and solvent (2022 - 2024).

The CSS + Hyb-SEN technology showed the most favorable outcomes, indicating its potential as a highly effective enhanced oil recovery (EOR) technique. This method showed significant improvement in oil recovery rates. However, in the CSS + solvent case, the results were comparable to the baseline CSS case, suggesting that adding solvent without nanocatalysts did not significantly enhance the overall recovery performance. The reduction in viscosity due to the solvent is the only effect related to this process, in contrast to the hybrid nanocatalyst technology that involves additional mechanisms as catalysts of the reaction.

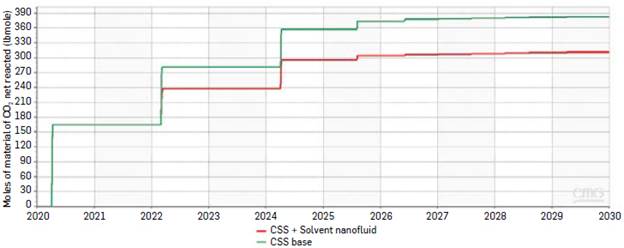

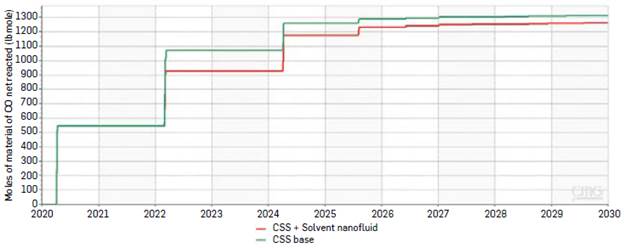

Likewise, each of the gases produced by the pseudo-aquathermolysis reaction for the base case and the implementation of hybrid technology is analyzed. Figure 8 shows CO2 production.

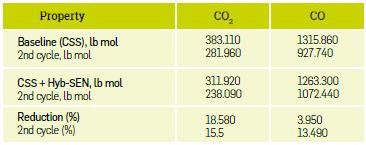

The CO2 generated in the hybrid technology is considerably less than that obtained in the base case by amounts of 311.92 and 383.11 lb mol, respectively. Also, for the second cycle, the CO2 generated for the CSS + nanofluid was 238.09 lb mol, while for CSS, it was 281.96 lb mol. The latter indicates that the implementation of hybrid technology reduces the production of CO2 released into the atmosphere due to the nanofluid effect until the sixth cycle.

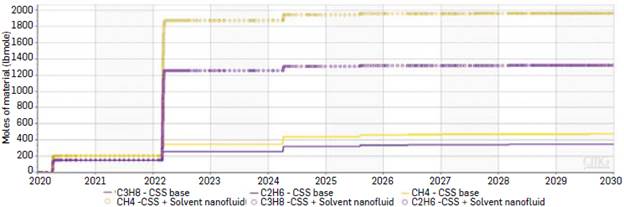

Figure 9 shows the estimation of CO production for the hybrid technology of CSS + naphtha-based nanofluids and the base case.

The production of CO obtained by the implementation of the Hyb-SEN for CSS is lower by 52.50 lb mol compared to conventional CSS, which in turn is equivalent to a reduction of approximately 3.95% due to the catalysis of the pseudo-aquathermolysis reaction as evidenced in the experimental tests carried out on the crude in the presence and absence of nanomaterials. For the second cycle, the reduction was 13.9%, with a CO reduction of 144.70 lb mol with respect to CSS.

On the other hand, the summary of the greenhouse gases produced by hybrid technology and the conventional cyclical steam injection is shown in Table 6. The results show a reduction in gases compared to the base case (greater than 18% for the CO2 production); this indicates that hybrid technology positively impacts on reducing the carbon footprint.

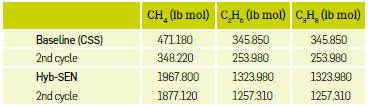

Additionally, the production of light hydrocarbon gases was estimated for both cases. The results are shown in Figure 10.

The light gases produced by conventional CSS + Solvent nanofluid are considerably higher than those obtained with CSS base. Table 7 shows the summary of gas production.

Low molecular weight hydrocarbon gases (methane, C2H6, C3H8) could be a source of energy, that is, as a replacement for natural gas in processes used in the plant, such as steam generation for reducing the effect of greenhouse gases. Since low molecular gases are released directly into the atmosphere, they can be 25 times more polluting than CO2.

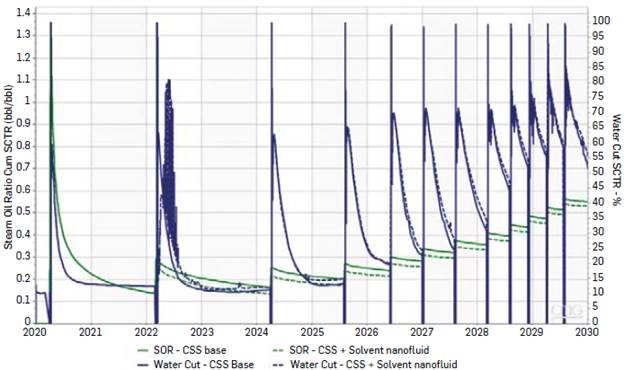

Additionally, Figure 11 shows the cumulative SOR and the water cut instantaneity of the two evaluated scenarios. As observed with the hybrid technology, there is a significant reduction of cumulative SOR, which means that the nanoparticles contribute to incremental oil production with the same injected steam compared to the CSS base scenario. However, the BSW instantaneity compared to the base case increased due to the change in the fluids' movement and the catalytic effect of nanoparticles in the second cycle and the permeability relative curves.

According to the results obtained in this stage, it is concluded that there is a high reduction of COx gases with the use of nanocatalysts, also generating an increase in oil production, achieving a more energy-efficient process with this hybrid technology.

ENVIRONMENTAL IMPACT CALCULATION

Following the proposed environmental indicators and methodology reported by Osma et al., 2019Osma, L., García, L., Pérez, R., Barbosa, C., Botett, J., Sandoval, J., & Manrique, E. (2019). Benefit-cost and energy efficiency index to support the screening of hybrid cyclic steam stimulation methods. Energies, 12(24), 4631. https://doi.org/10.3390/en12244631

https://doi.org/10.3390/en12244631...

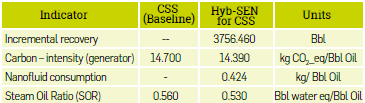

, the environmental impact calculation was performed for the hybrid technology scenario and baseline. The carbon intensity index results were obtained at this stage considering the CO2 production from steam generation supported by the UPME emissions calculation tool for the scenario evaluated Hyb-SEN, with a steam rate equal to the baseline considering the CO2 generated in the reservoir and due to steam generation. Table 8 shows the results for the CSS baseline and Hyb-SEN for CSS.

Improvements on environmental indicators are obtained for hybrid technology concerning conventional steam technology, reflected in a lower carbon-intensity index and reduction of SOR, which indicates better energy efficiency requiring less steam per barrel of oil produced and a lower water cut.

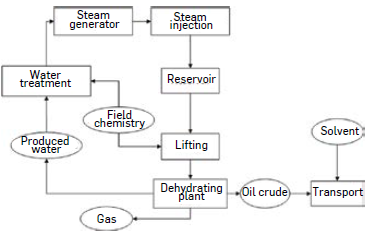

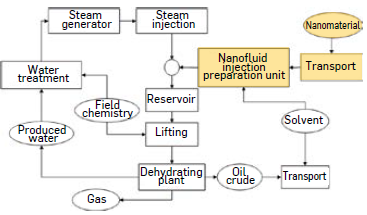

Likewise, as a complement to the environmental impact analysis, Figure 12 shows the flow diagram of the relevant unit operations that occurred in a conventional cyclical steam injection process.

In contrast, Figure 13 shows the process diagram for hybrid technology that presents an additional benefit from the use of naphtha-based nanofluids in the use of raw materials in situ with the technology used for crude oil transportation. The latter could imply a subsequent reduction in their use, considering the current naphtha requirements in the conventional process and comparing it with that of hybrid technology.

CONCLUSIONS

o The development of this innovative numerical simulation methodology for hybrid cyclic steam injection processes enhanced with solvent and nanocatalysts enabled an accurate representation of numerical effects observed in each steam injection cycle. This approach effectively captured the impact of nanocatalyst presence (or absence) on the production of gases associated with pseudo-aquathermolysis reactions.

o The hybrid technology showed a notable reduction greater than 18% for the CO2 production compared to conventional cyclical steam injection. This is attributable to the presence of nano-catalysts, which generate an increase in oil production, thus achieving a more energy-efficient process with this technology.

o The best environmental indicators were obtained with the hybrid technology concerning conventional steam technology, reflected on a lower carbon-intensity index and reduction of SOR. This indicates better energy efficiency by requiring less steam per barrel of oil produced in both cases, and a lower water cut.

o The environmental impact analysis of the scenarios evaluated concerning the base case aled to determine a positive impact regarding improvement in energy efficiency and a reduction of carbon footprint reflected in lower carbon intensity, among others. The foregoing proves that hybrid steam technology with naphtha-based nanofluids not only generates positive impacts on productivity, that is, greater recovery compared to the conventional technique, but also positively impacts energy efficiency, and reduces the carbon footprint.

ACKNOWLEDGEMENTS

The authors would like to thank Ecopetrol, S.A. specially, the Vice Presidency of Science, Technology & Innovation and ICPET for the permission to publish this paper.

REFERENCES

- Amrollahi Biyouki, A., Hosseinpour, N., & Nassar, N. N. (2018). Pyrolysis and oxidation of asphaltene-born coke-like residue formed onto in situ prepared NiO nanoparticles toward advanced in situ combustion enhanced oil recovery processes. Energy & fuels, 32(4), 5033-5044. https://doi.org/10.1021/acs.energyfuels.8b00638

» https://doi.org/10.1021/acs.energyfuels.8b00638 - Bera, A., & Babadagli, T. (2015). Status of electromagnetic heating for enhanced heavy oil/bitumen recovery and future prospects: a review. Applied Energy, 151, 206-226 https://doi.org/10.1016/j.apenergy.2015.04.031

» https://doi.org/10.1016/j.apenergy.2015.04.031 - Biyouki, A. A., Hosseinpour, N., Bahramian, A., & Vatani, A. (2017). In-situ upgrading of reservoir oils by in-situ preparation of NiO nanoparticles in thermal enhanced oil recovery processes. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 520, 289-300. https://doi.org/10.1016/j.colsurfa.2017.01.089

» https://doi.org/10.1016/j.colsurfa.2017.01.089 - Cárdenas, J. A. B. (2014). Modelo cineticopara determinar parametros cineticos de lapirolisis de la cascarilla de café (Doctoral dissertation, Uniandes). https://repositorio.uniandes.edu.co/bitstreams/97dbd428-b767-4d94-8ffd-81baa2d79108/download

» https://repositorio.uniandes.edu.co/bitstreams/97dbd428-b767-4d94-8ffd-81baa2d79108/download - Dziejarski, B., Krzyżyńska, R., & Andersson, K. (2023). Current status of carbon capture, utilization, and storage technologies in the global economy: A survey of technical assessment. Fuel, 342, 127776. https://doi.org/10.1016/j.fuel.2023.127776

» https://doi.org/10.1016/j.fuel.2023.127776 - Farajzadeh, R., Glasbergen, G., Karpan, V., Mjeni, R., Boersma, D., Eftekhari, A., . . . Bruining, J. (2022). Improved oil recovery techniques and their role in energy efficiency and reducing CO2 footprint of oil poduction. Journal of Cleaner Production, 369, 133308. https://doi.org/10.1016/j.jclepro.2022.133308

» https://doi.org/10.1016/j.jclepro.2022.133308 - Franco, C. A., Nassar, N. N., Montoya, T., Ruíz, M. A., & Cortés, F. B. (2015). Influence of asphaltene aggregation on the adsorption and catalytic behavior of nanoparticles. Energy & Fuels, 29, 1610-1621. https://doi.org/10.1021/ef502786e

» https://doi.org/10.1021/ef502786e - Franco, C Flórez, A., & Ochoa, M. (2008). Análisis de la cadena de suministros de biocombustibles en Colombia. Revista de Dinámica de Sistemas, 4(2), 109-133. https://www.researchgate.net/profile/Camila-Ochoa/publication/263816420_Analisis_de_la_cadena_de_suministro_de_biocombustibles_en_Colombia/ links/57d04b7108ae6399a389d710/Analisis-de-la-cadena-de-suministro-de-biocombustibles-en-Colombia.pdf

» https://www.researchgate.net/profile/Camila-Ochoa/publication/263816420_Analisis_de_la_cadena_de_suministro_de_biocombustibles_en_Colombia/ links/57d04b7108ae6399a389d710/Analisis-de-la-cadena-de-suministro-de-biocombustibles-en-Colombia.pdf - Friedman, H. L. (1964). Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. Journal of Polymer Science Part C: Polymer Symposia, 6(1), 183-195. https://doi.org/10.1002/polc.5070060121

» https://doi.org/10.1002/polc.5070060121 - García - Duarte, H. A., Ruiz - Cañas, M. C., Quintero, H., Medina, O. E., Lopera, S. H., Cortés, F. B., & Franco, C . A. (2024). Development of Nanofluid -Based Solvent as a Hybrid Technology for In-Situ Heavy Oil Upgrading During Cyclic Steam Stimulation Applications. ACS Omega, 9(39), 40511-40521. https://doi.org/10.1021/acsomega.4c03517

» https://doi.org/10.1021/acsomega.4c03517 - García-Duarte, H. A., Ruiz-Cañas, M. C., & Pérez-Romero, R. A. (2023). Innovative Experimental Design for the Evaluation of Nanofluid - Based Solvent as a Hybrid Technology for Optimizing Cyclic Steam Stimulation Applications. Energies, 16, 373. https://doi.org/10.3390/en16010373

» https://doi.org/10.3390/en16010373 - Hamedi Shokrlu, Y., & Babadagli, T. (2013). In-Situ Upgrading of Heavy Oil/Bitumen During Steam Injection by Use of Metal Nanoparticles: A Study on In-Situ Catalysis and Catalyst Transportation. SPE Res Eval & Eng,, 16(3), 333-344. https://doi.org/10.2118/146661-PA

» https://doi.org/10.2118/146661-PA - Hashemi, R., Nassar, N. N., & Pereira Almao, P. (2013). Enhanced heavy oil recovery by in situ prepared ultradispersed multimetallic nanoparticles: A study of hot fluid flooding for Athabasca bitumen recovery. Energy & Fuels, 27, 2194-2201. https://doi.org/10.1021/ef3020537

» https://doi.org/10.1021/ef3020537 - Hou, J., Li, C., Gao, H., Chen, M., Huang, W., Chen, Y., & Zhou, C. (2017). Recyclable oleic acid modified magnetic NiFe2O4 nanoparticles for catalytic aquathermolysis of Liaohe heavy oil. Fuel, 200, 193-198. https://doi.org/10.1016/j.fuel.2017.03.005

» https://doi.org/10.1016/j.fuel.2017.03.005 - Husein, M. M., & Alkhaldi, S. J. (2014). In situ preparation of alumina nanoparticles in heavy oil and their thermal cracking performance. Energy and Fuels, 28, 6563-6569. https://doi.org/10.1021/ef5012963

» https://doi.org/10.1021/ef5012963 - Hyne, J. B. (1986). Aquathermolysis: a synopsis of work on the chemical reaction between water (steam) and heavy oil sands during simulated steam stimulation. https://openlibrary.org/books/OL19361916M/Aquathermolysis

» https://openlibrary.org/books/OL19361916M/Aquathermolysis - Iskandar, F., Dwinanto, E., Abdullah, M., & Muraza, O. (2016). Viscosity reduction of heavy oil using nanocatalyst in aquathermolysis reaction. KONA Powder and Particle Journal, 33, 3-16. https://doi.org/10.14356/kona.2016005

» https://doi.org/10.14356/kona.2016005 - Kaminski, T., Anis, S. F., Husein, M. M., & Hashaikeh, R. (2018). Hydrocracking of Athabasca VR Using NiO-WO3 Zeolite-Based Catalysts. Energy and Fuels, 32, 2224-2233. https://doi.org/10.1021/acs.energyfuels.7b03754

» https://doi.org/10.1021/acs.energyfuels.7b03754 - Montoya, T., Argel, B. L., Nassar, N. N., Franco, C . A. , & Cortés, F. B. (2016). Kinetics and mechanisms of the catalytic thermal cracking of asphaltenes adsorbed on supported nanoparticles. Petroleum Science, 13, 561-571. https://doi.org/10.1007/s12182-016-0100-y

» https://doi.org/10.1007/s12182-016-0100-y - Nassar, N. N. , Franco, C . A. , Montoya, T. , Cortés, F. B. , & Hassan, A. (2015). Effect of oxide support on Ni-Pd bimetallic nanocatalysts for steam gasification of n-C7 asphaltenes. Fuel, 156, 110-120. https://doi.org/10.1016/j.fuel.2015.04.031

» https://doi.org/10.1016/j.fuel.2015.04.031 - Nassar, N. N. , Hassan, A. , Luna, G., & Pereira-Almao, P. (2013). Kinetics of the catalytic thermo-oxidation of asphaltenes at isothermal conditions on different metal oxide nanoparticle surfaces. Catalysis today, 207, 127-132. https://doi.org/10.1016/j.cattod.2012.04.054

» https://doi.org/10.1016/j.cattod.2012.04.054 - Osma, L., García, L., Pérez, R., Barbosa, C., Botett, J., Sandoval, J., & Manrique, E. (2019). Benefit-cost and energy efficiency index to support the screening of hybrid cyclic steam stimulation methods. Energies, 12(24), 4631. https://doi.org/10.3390/en12244631

» https://doi.org/10.3390/en12244631 - Pretell, V., Ubillas, C., Ruiz, C., Rodriguez, J., & Ramos, W. (2020). Evaluación de los Parámetros Cinéticos por Análisis Termogravimétrico del Esquisto en la Formación Muerto, Talara-Perú. LACCEI Inc. https://www.academia.edu/92509830/Evaluaci%C3%B3n_de_los_Par%C3%A1metros_Cin%C3%A9ticos_por_An%C3%A1lisis_Termogravim%C3%A9trico_del_Esquisto_en_la_Formaci%C3%B3n_Muerto_Talara_Per%C3%BA

» https://www.academia.edu/92509830/Evaluaci%C3%B3n_de_los_Par%C3%A1metros_Cin%C3%A9ticos_por_An%C3%A1lisis_Termogravim%C3%A9trico_del_Esquisto_en_la_Formaci%C3%B3n_Muerto_Talara_Per%C3%BA - Ruiz-Cañas, M. C., Garcia-Duarte, H. A., Perez-Romero, R. A., & Manrique, E. (2023, June). Numerical Simulation of Cyclic Steam Stimulation and Solvents Enhanced With Nanocatalysts: A Methodologic Approach. In SPE Latin America and Caribbean Petroleum Engineering Conference (p. D011S006R003). SPE. https://doi.org/10.2118/213176-MS

» https://doi.org/10.2118/213176-MS - Shah, A., Fishwick, R., Wood, J., Leeke, G., Rigby, S., & Greaves, M. (2010). A review of novel techniques for heavy oil and bitumen extraction and upgrading. Energy & Environmental Science, 3(6), 700-714. https://doi.org/10.1039/b918960b

» https://doi.org/10.1039/b918960b - Tang, X. D., Liang, G. J., Li, J. J., Wei, Y. T., & Dang, T. (2017). Catalytic effect of in-situ preparation of copper oxide nanoparticles on the heavy oil low-temperature oxidation process in air injection recovery. Petroleum Science and Technology, 35(13), 1321-1326. https://doi.org/10.1080/10916466.2017.1318145

» https://doi.org/10.1080/10916466.2017.1318145 - Yi, S., Babadagli, T., & Andy Li, H. (2018). Use of nickel nanoparticles for promoting aquathermolysis reaction during cyclic steam stimulation. SPE Journal, 23(01), 145-156. https://doi.org/10.2118/186102-PA

» https://doi.org/10.2118/186102-PA

AUTHORS

| María Carolina Ruiz Cañas |

SGS Colombia S.A.S., Bogotá, Colombia. ORCID: https://orcid.org/0000-0001-7613-314X e-mail: maria.ruizca@ecopetrol.com.co |

| Hugo Alejandro García Duarte |

Ecopetrol S.A. - Instituto Colombiano del Petróleo y Energías de la Transición (ICPET), Piedecuesta, Santander, Colombia. ORCID: https://orcid.org/0000-0003-1335-1849 e-mail: hugo.garcia@ecopetrol.com.co |

| Christian David Patiño Ramírez |

SGS Colombia S.A.S., Bogotá, Colombia. ORCID: https://orcid.org/0009-0004-8376-7174 e-mail: christian.patinora@ecopetrol.com.co |

How to cite

Ruiz-Cañas, M.C., García-Duarte, H.A., & Patiño-Ramírez, C.D. (2024). An innovative simulation methodology for hybrid technology with nanocatalyst-enhanced solvent (HYB-SEN) as an alternative for improving environmental indicators in cyclic steam stimulation. Ciencia, Tecnología y Futuro (CT&F), 14(2), 67–78.

Publication Dates

-

Date of issue

Jul-Dec 2024

History

-

Received

29 Aug 2024 -

Reviewed

16 Dec 2024 -

Accepted

18 Dec 2024