ABSTRACT

This paper presents a novel V-nets-Based Alarm Management (VBAM) methodology designed to enhance supervision and safety in Green Hydrogen Plants (GHPs). The proposed approach integrates visual modeling and temporal pattern analysis to accurately detect and manage alarms, seeking to reduce false positives and optimize response times. The methodology starts with a Preliminary Hazard and Operability (HAZOP) analysis to identify potential hazards and critical operational conditions, which are the foundation for constructing V-nets that map the temporal relationships between discrete events. By systematically capturing event sequences and their interdependencies, the VBAM approach allows for early fault detection and a proactive alarm management system fit for varying operational scenarios. A case study of the EL30N Green Hydrogen Plant proves the efficacy of the VBAM methodology in reducing downtime, improving system safety, and enhancing overall operational efficiency. This work provides a comprehensive framework for addressing discrete event challenges in alarm management, paving the way for safer and more resilient practices in green hydrogen production. Future directions will include expanding the application of VBAM to other operational phases and incorporating real-time analytics for further performance optimization.

KEYWORDS:

Green Hydrogen Plants; alarm management; V-nets; diagnosis; DES

RESUMEN

Este artículo presenta una nueva metodología de gestión de alarmas basada en redes V (VBAM) diseñada para mejorar la supervisión y la seguridad en plantas de hidrógeno verde (GHP). El enfoque propuesto integra el modelado visual y el análisis de patrones temporales para detectar y gestionar alarmas con precisión, con el objetivo de reducir los falsos positivos y optimizar los tiempos de respuesta. La metodología comienza con un análisis preliminar de peligros y operabilidad (HAZOP) para identificar peligros potenciales y condiciones operativas críticas, formando la base para construir redes virtuales que mapeen las relaciones temporales entre eventos discretos. Al capturar sistemáticamente secuencias de eventos y sus interdependencias, el enfoque VBAM permite la detección temprana de fallas y un sistema de gestión de alarmas proactivo que se adapta a diferentes escenarios operativos. Un estudio de caso de la planta de hidrógeno verde EL30N demuestra la eficacia de la metodología VBAM para reducir el tiempo de inactividad, mejorar la seguridad del sistema y mejorar la eficiencia operativa general. Este trabajo proporciona un marco integral para abordar los desafíos de eventos discretos en la gestión de alarmas, allanando el camino para prácticas más seguras y resilientes en la producción de hidrógeno verde. Las direcciones futuras incluyen ampliar la aplicación de VBAM a otras fases operativas e incorporar análisis en tiempo real para una mayor optimización del rendimiento.

PALABRAS CLAVE:

Plantas de Hidrógeno Verde; gestión de alarmas; V-nets; diagnóstico; DES

INTRODUCTION

As the world shifts towards sustainable and low-carbon energy solutions, green hydrogen has emerged as a pivotal resource due to its potential to revolutionize the global energy landscape (Kovac et al., 2021Kovač, A., Paranos, M., & Marcius, D. (2021). Hydrogen in energy transition: A review. International Journal of Hydrogen Energy, 46(16), 10016-10035. https://doi.org/10.1016/j.ijhydene.2020.11.256

https://doi.org/10.1016/j.ijhydene.2020....

; IEA, 2019). Produced through the electrolysis of water using renewable energy sources, green hydrogen is a clean alternative for fuel cells, energy storage, and various industrial applications (Zheng et al., 2024Zheng, W., Zheng, X., & Zhu, X. (2024). Promoting integration of industry and vocational education: Exploring stakeholder intentions of hydrogen energy industry. International Journal of Hydrogen Energy, 52, 454-464.. https://doi.org/10.1016/j.ijhydene.2023.06.072

https://doi.org/10.1016/j.ijhydene.2023....

, March 9; Scheller et al., 2023Scheller, F., Wald, S., Kondziella, H., Gunkel, P. A., & Bruckner, T. (2023). Future role and economic benefits of hydrogen and synthetic energy carriers in Germany: A review of long-term energy scenarios. Sustainable Energy Technologies and Assessments, 56, 103037. https://doi.org/10.1016/j.seta.2023.103037

https://doi.org/10.1016/j.seta.2023.1030...

). However, the "clean" classification of hydrogen is contingent upon its production route, with significant environmental benefits obtained only when renewable energy inputs are used (Rajapriya & Dangate, 2023Rajapriya, R., & Dangate, M. S. (2023). Hydrogen as a fuel cell. Integrated Green Energy Solutions, 1, 45-59. https://doi.org/10.1002/9781119847564.ch4

https://doi.org/10.1002/9781119847564.ch...

). This distinction underscores the critical importance of efficient, safe, and reliable operation of Green Hydrogen Plants (GHPs), where alarm management plays a crucial role in maintaining operational integrity (Ajanovic et al. 2024Ajanovic, A., Sayer, M., & Haas, R. (2024). On the future relevance of green hydrogen in Europe. Applied Energy, 358, 122586. https://doi.org/10.1016/j.apenergy.2023.122586

https://doi.org/10.1016/j.apenergy.2023....

). Alarm management in industrial settings such as GHPs is a complex challenge, particularly due to the intricate processes and safety risks associated to hydrogen production (Feng et al., 2024Feng, L., Gu, Y., Pang, J., Jiang, L., Liu, J., Zhou, H., & Babaee, S. (2024). Risk identification and safety technology for hydrogen production from natural gas reforming. ChemBioEng Reviews, 11(2), 386-405. https://doi.org/10.1002/cben.202300049

https://doi.org/10.1002/cben.202300049...

). Effective alarm management systems must not only differentiate between genuine alarms and false positives, but also facilitate timely responses to critical conditions. Traditional alarm management methods often struggle with high rates of false positives, which can lead to operator desensitization and delayed responses to real hazards. Moreover, optimizing the response time and prioritization of alarms remains an ongoing challenge, requiring innovative approaches that can dynamically adapt to evolving operational scenarios (Capacho et al., relying on discrete event modelling to improve alarm detection and response in GHPs. The VBAM methodology builds on a rigorous Preliminary Hazard and Operability (HAZOP) analysis to identify potential hazards and establish key event types, including alarms, operational actions, and critical conditions. Through the construction of V-nets that map the temporal and causal relationships between these events, the methodology seeks to reduce false positives, optimize response times, and enhance overall system safety and efficiency. The primary contributions of this paper are threefold: (1) the development of a comprehensive alarm management framework tailored for the unique operational demands of GHPs, (2) a detailed comparative analysis demonstrating the superiority of VBAM over conventional alarm management techniques in terms of fault detection and response optimization, and (3) the application of the VBAM methodology to a real-world case study of the EL30N Green Hydrogen Plant, showcasing its practical benefits and potential for broader industrial adoption. The remainder of this paper is structured as follows: Section 2 reviews the state of the art in alarm management methodologies, highlighting existing gaps and the need for advanced solutions like VBAM. Section 3 outlines the theoretical framework of VBAM, with an emphasis on the formal definitions of discrete events and V-nets. Section 4 presents a case study applying VBAM to the EL30N Green Hydrogen Plant, including detailed experimental results and analysis. Finally, Section 5 discusses the conclusions, limitations, and potential future work, which includes extending VBAM to other operational phases and incorporating realtime analytics for enhanced performance. Finally, this study aims to provide a robust and scalable solution for alarm management in GHPs, contributing to the broader goal of advancing green hydrogen technology as a cornerstone of a sustainable energy future.

2 STATE OF THE ART

ln the realm of alarm management for green hydrogen plants, the theorical framework revolves around a novel methodology grounded in discrete event formalism. Discrete events, within this context, represent distinct occurrences or happenings in the operational landscape of a hydrogen plant. These events can encompass a spectrum of scenarios, ranging from routine operational states to exceptional and potentially hazardous conditions. Operational actions, on the other hand, are specific activities or responses undertaken at the plant to ensure its continued safe and efficient functioning. These actions are intrinsically tied to the discrete events, often serving as response to deviations from normal operating conditions, or as proactive measures to maintain system integrity. A sequence of events refers to the ordered occurrence of discrete events over time, creating a chronological narrative of the plant's operational dynamics. The analysis of these sequences provides insights into the interdependencies and interactions between different events, contributing to a comprehensive understanding of the plant's behavior. Furthermore, this temporal sequence represents the flow of activity created by the system. In these temporal sequences, time is represented by a discrete set of time points that are completely ordered and whose granularity is sufficiently thin when compared to the observable dynamics presuming that there is no error. Thus,, an event type may be referred to as an event for short.

In the context of alarm management, abnormal situations represent deviations or anomalies from the expected or normal operational states. These situations can pose risks to the system's integrity, and timely detection and response are crucial to prevent adverse consequences. Conversely, normal situations denote the standard and expected operational states of the hydrogen plant, where all parameters and processes align with predefined norms. Understanding the distinction between normal and abnormal situations is the basis for effective alarm management, allowing for the timely identification of deviations, and the start of appropriate operational actions. The theoretical framework for alarm management in green hydrogen plants relying on discrete event formalism involves a nuanced understanding of discrete events, operational actions, sequences of events, abnormal situations, and normal situations. This framework provides a structured approach to analyzing and responding to the dynamic operational landscape, enhancing safety and efficiency in hydrogen plant operations. In the dynamic realm of renewable energy, hydrogen stands out as a key player to address global energy and environmental challenges. As hydrogen production gains traction as a clean energy solution, the operation of hydrogen production plants requires an effective alarm management system to ensure integrity, safety, and productivity. Hydrogen plants involve complex chemical reactions, intricate equipment configurations, and sophisticated process controls, emphasizing the need for a well-structured alarm management strategy (Kumar et al., 2023Kumar, S., Baalisampang, T., Arzaghi, E., Garaniya, V., Abbassi, R., & Salehi, F. (2023). Synergy of green hydrogen sector with offshore industries: Opportunities and challenges for a safe and sustainable hydrogen economy. Journal of Cleaner Production, 384, 135545. https://doi.org/10.1016/j.jclepro.2022.135545

https://doi.org/10.1016/j.jclepro.2022.1...

June). This article explores the critical domain of alarm management in hydrogen production, covering aspects such as rationalization, prioritization, operator training, and continuous improvement. Beyond theoretical foundations, the discussion highlights the intricate interplay between technology, human intervention, and the pursuit of sustainable energy solutions. With hydrogen as a cornerstone of the green energy future, a deep understanding of alarm management becomes pivotal for unlocking the full potential of hydrogen production plants and ensuring safety in Green Hydrogen Plants. Key considerations in green hydrogen plants include the need for a robust alarm system to swiftly alert operators to abnormal conditions, whikch is crucial given the associated risks of explosions or fires. Managing risk through monitoring tools, alarms, and fire detection systems is vital. Operations management software and information-driven operations play pivotal roles in optimizing green hydrogen production, ensuring effective alarm management, and adhering to safety standards. Automated data-driven approaches are instrumental in efficiently scaling up green hydrogen production facilities. Alarm management is essential to ensure the safety and efficiency of green hydrogen plants. A comprehensive approach involves the implementation of a robust alarm system, risk management tools, operation management software, and information-driven operations. Safety standards for hydrogen systems also emphasize the importance of effective alarm management. The Green Hydrogen Project by Honeywell Connected Enterprise exemplifies an end-to-end alarm life-cycle management system, reducing operator workload, improving situational awareness, and minimizing process upsets. Table 1 presents a comparative analysis aims to explore various perspectives on the role of green hydrogen in the energy transition, focusing on its applications, challenges, and technological advancements. The selected papers cover diverse aspects such as offshore hydrogen infrastructure, synergy between green hydrogen and other industries, techno-economic analyses of hydrogen production methods, safety standards, and geopolitical implications of hydrogen deployment. Each study provides valuable insights into the evolving landscape of green hydrogen, highlighting opportunities and risks associated to its integration into global energy systems.

This table synthesizes the core focus, insights, technological aspects, economic implications, geopolitical and regulatory considerations, and safety and environmental impacts from each paper. It provides a structured comparison to highlight how each study contributes uniquely to the broader understanding of green hydrogen's role in the energy transition.

The control system architecture for a hydrogen hub is crucial for seamless and secure operations. Integrated control systems, including SCADA and embedded control mechanisms, enable realtime monitoring, data acquisition, and effective decision-making. Advanced technology safety systems detect hazards and implement automatic shutdown procedures, ensuring personnel, infrastructure, and environmental safety. The human-machine interface enhances situational awareness, and production analytics promptly notify operators of abnormal conditions, employing advanced algorithms for proactive issue resolution. Demand analytics contribute to efficient resource allocation, and alarm rationalization prevents overload by evaluating and prioritizing alarms. This control system architecture, combining safety measures, human-machine interaction, analytics, and optimized alarms, establishes a robust and efficient hydrogen ecosystem for a future of low-carbon and clean energy. In the realm of green hydrogen plants, traditional alarm systems face challenges due to the complexity of dynamic environments. Novel alarm management methodologies are emerging as powerful tools to revolutionize supervision. These methodologies, rooted in technologies such as artificial intelligence and machine learning, offer a proactive and predictive approach. Examples include Chronicle-Based Alarm Management, Superalarms Generation, AI-Powered Alarm Management, Model-Based Alarm Management, Integrated Alarm and Process Optimization, and Human-Machine Collaboration. Table 2 provides a structured comparison of the selected papers, focusing on their contributions to alarm management, fault detection, and the integration of advanced technologies in various industrial contexts. Each entry highlights key insights, technological aspects, economic implications regulatory considerations, and safety impacts, offering a comprehensive overview of the current state of research in these areas.

The new methodology V-nets Based Alarm Management described in the next section stands as an approach tailored for the intricate operational landscape of green hydrogen plants (GHPs). This methodology addresses the complexities of GHPs through comprehensive risk analysis, context-aware event types, and dynamic, responsive V-nets. This approach starts with a thorough Preliminary Hazard Analysis (HAZOP), systematically identifying potential hazards and vulnerabilities. Subsequently, the determination of event types is context-aware, and linked to GHP operational realities. The heart of the methodology lies in V-nets, offering a dynamic framework that captures temporal intricacies, paving the way for a proactive and predictive approach to alarm management. Through the meticulous construction and analysis of V-nets, the methodology enables enhanced decision-making, allowing operators to proactively refine strategies and optimize responses. The VBAM can offer a pathway to safer, more efficient, and resilient practices in the realm of green hydrogen production.

3 THEORETICAL FRAMEWORK OF VBAM

The supervision and operational efficiency of industrial plants, particularly those involved in hydrogen production, have been the focus of numerous methodologies, each designed to tackle specific challenges within these complex systems. While current approaches such as Chronicle-Based Alarm Management, Superalarms Generation, AI-Powered Alarm Management, Model-Based Alarm Management, Integrated Alarm and Process Optimization, and Human-Machine Collaboration have made significant strides, they often fall short in addressing critical issues related to simultaneous occurrences, false positives, and event repetitions within alarm sequences. For instance, Chronicle-Based Alarm Management, as introduced by Vasquez (Vasquez et al. 2015), effectively captures temporal and causal relationships between alarms and operational actions through a chronological analysis of events. Although this approach provides valuable insights into event sequences, it lacks a detailed exploration of simultaneous occurrences, false positives, and event repetitions, which are crucial for robust alarm management (Fanti et al., 2012Fanti, M. P., Mininel, S., Ukovich, W., & Vatta, F. (2012). Modelling alarm management workflow in healthcare according to IHE framework by coloured Petri nets. Engineering Applications of Artificial Intelligence, 25(4), 728-733. https://doi.org/10.1016/j.engappai.2010.11.003

https://doi.org/10.1016/j.engappai.2010....

). Similarly, methodologies such as Superalarms Generation and AI-Powered Alarm Management rely on advanced data-driven analytics and machine learning techniques to enhance alarm systems and optimize plant conditions (Capacho et al. 2017Capacho, J. V., Subias, A., Trave-Massuyes, L., & Jimenez, F. (2017). Alarm management via temporal pattern learning. Engineering Applications of Artificial Intelligence, 65, 506-516. https://doi.org/10.1016/j.engappai.2017.07.008

https://doi.org/10.1016/j.engappai.2017....

and Ni & Li, 2024Ni, C., & Li, S. C. (2024). Machine learning enabled industrial IoT security: Challenges, trends, and solutions. Journal of Industrial Information Integration, 100549. https://doi.org/10.1016/j.jii.2023.100549

https://doi.org/10.1016/j.jii.2023.10054...

). Despite these technological advancements, they do not adequately address the complexities of handling simultaneous occurrences and repetitions within event sequences, nor do they specifically focus on reducing false positives. Further, Model-Based Alarm Management and Integrated Alarm and Process Optimization rely on dynamic process models and operational variables for decision-making. However, existing research in these areas often overlooks the impact of simultaneous events and the need for more precise handling of false positives and repetitions. Human-Machine Collaboration seeks to enhance the synergy between operators and advanced decision support systems but, at the same time, similarly lacks targeted studies on the intricate dynamics of event sequences, including the issues of simultaneous occurrences and false positives.

Recognizing these gaps, we propose the VBAM (V-nets-Based Alarm Management) methodology as a comprehensive solution to these challenges. VBAM is designed to address the specific needs of alarm management by incorporating studies focused on simultaneous occurrences, false positives, and event repetitions within event sequences, which are often neglected in existing approaches. Grounded in the formalism of V-nets as proposed by Vasquez, VBAM aims to provide a more robust and effective framework for the supervision of green hydrogen plants. This innovative approach not only fills the void left by current methodologies but also enhances the overall reliability and safety of alarm management systems in complex industrial settings. A unique formalism known as V-nets was introduced as a method of modelling and evaluating discrete event dynamic systems, which are characterized by time-evolving behaviours and specific event occurrences. With specific features such as places displayed as squares and transitions as connected arcs, V-nets use a graphical representation akin to Petri nets or the Chronicles (Fanti et a., 2012Fanti, M. P., Mininel, S., Ukovich, W., & Vatta, F. (2012). Modelling alarm management workflow in healthcare according to IHE framework by coloured Petri nets. Engineering Applications of Artificial Intelligence, 25(4), 728-733. https://doi.org/10.1016/j.engappai.2010.11.003

https://doi.org/10.1016/j.engappai.2010....

). In addition, V-nets feature a variety of characteristics for defining system behaviour, such as guidelines for handling concurrent events, transition firing, and false-positive analysis, among others. Compared to other formalisms, V-nets can represent and detect defects in complex systems more accurately and efficiently thanks to these qualities. As a result, V-nets are a reliable tool for modelling and analysing complex systems, notably in the fields of industrial applications and Cyber-Physical Systems. Moreover, by displaying the discrete events and their connections inside the system graphically, V-nets can be used to diagnose problems with energy efficiency. It is possible to diagnose anomalous energy consumption patterns by modelling the system with V-nets. This makes it easier to optimize the system by enabling the examination of event sequences that lead to increased energy consumption. Additionally, V-nets facilitate the replacement or repair of malfunctioning components that may be the source of excessive energy consumption, leading to the creation of a system that uses less energy. In sum, the V-nets formalism provides a powerful way to find energy efficiency problems in complex systems.

Definition 1: A V-net (VN ) is defined as the tuple ⟨ξ, , G, INIT, END, Frec, R ⟩ such that:

ξ ⊆ E, in which ξ is the set of events involved in the VN,

T is the set of temporal constraints of the V-net,

- G = (V, A, Ev) is a directed graph in which:

◊ V represents the events of ξ

◊ Arcs A represents the different time constraints between events.

◊ Ev:(True/false) represents the activation or deactivation of arcs according to the evolution of the timed observations.

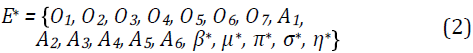

INIT corresponds to the event that initiates the event sequence, see Fig. 1

END corresponds to the event that ends the event sequence, see Fig. 1. In a V-net, the initial event and the final event could be the same.

Frec corresponds to the frequencies for each event in the event sequence. For example, in the interval or temporal constraint afa [I-, I+]fbb ; and fa(b) is the frequency of the event a (b) on the interval [I-, I+]

- R contains the set of logical predicates that correspond to the restrictions and warnings that confirm the V-net recognition. Examples:

◊ Frec(a):5 This indicates that the event a had occurred 5 times.

◊ Frec(a):1 ∧ Frec(b):1 This expression indicates that the event a and the event b had occurred one time each.

◊ Warning: a=b This indicates that the date of occurrence of the event a and event b are the same or these are so close that can be determined as simultaneous.

In the domain of modern industrial processes, where the pursuit of efficiency, safety, and reliability is paramount, the emergence of innovative methodologies is a continuous endeavor. A notable addition to this landscape is the V-nets-based Alarm Management methodology. This approach is a fusion of advanced technologies and proactive risk management, presenting a novel framework for optimizing alarm systems within intricate operational environments. The V-nets methodology starts with a meticulous Hazard and Operability (HAZOP) analysis, a foundational practice in process safety engineering. This systematic exploration identifies potential hazards and vulnerabilities within the operational landscape.

Subsequently, the methodology strategically progresses towards delineating pivotal event types, including alarms, operational actions, and critical conditions. These meticulously defined event types form the foundational elements for constructing a dynamic and responsive alarm management system. The essence of the V-nets methodology lies in its ability to craft event sequences, encapsulating a spectrum of scenarios from normal operational states to abnormal conditions. The thorough orchestration of these event sequences establishes a comprehensive library, laying the groundwork for the creation of V-net. These networks, excelling in illustrating causal relationships between events, become invaluable tools for capturing the temporal intricacies governing processes. V-nets offer a dynamic framework capable of capturing and analyzing the evolution of events over time. This methodology, rooted in data-driven precision and predictive foresight, propels alarm management to new heights. By leveraging the power of V-nets, practitioners gain the ability to navigate the intricate web of operational dynamics, anticipate potential anomalies, and devise strategies for optimized responses. As the broader industrial landscape continues to evolve, the V-nets-based Alarm Management methodology emerges as a beacon of innovation, offering a pathway to safer, more efficient, and resilient operational practices. Summarized below are the four steps of the VBAM methodology:

Preliminary Hazard Analysis: Begin with a comprehensive Hazard and Operability (HAZOP) analysis to identify potential hazards and vulnerabilities within the operational context.

Event Type Determination: Curate pivotal event types, including alarms, operational actions, and critical conditions, based on insights from the HAZOP analysis.

Event Sequence Generation: Create diverse event sequences representing different operational scenarios, capturing both normal and abnormal conditions.

V-nets Construction and Analysis: Craft V-nets to depict causal relationships between events, forming a dynamic framework for analyzing event evolution and optimizing alarm management.

STEP 1: PRELIMINARY HAZARD ANALYSIS

The VBAM methodology starts with a Preliminary Hazard Analysis (HAZOP), a crucial phase aimed at systematically identifying hazards and vulnerabilities within the operational context of a green hydrogen plant or similar industrial process. In this step, a team of multidisciplinary experts, including process engineers and safety professionals, performs an in-depth examination of the plant's design, operations, and processes. The objective is to detect deviations from normal operating conditions that could compromise system integrity by breaking down plant operations into discrete units. Mathematically, the hazard identification process can be expressed as a function H(x) that maps each operational unit x into a set of identified hazards H:

where x represents discrete operational units such as equipment, procedures, or human actions, and hi- represents potential hazards such as equipment failures, process deviations, or human errors. The HAZOP analysis uses probability functions P(hi) to quantify the likelihood of each hazard occurring and its potential impact on the system. The insights gained facilitate the selection of critical event types and sequences, forming the foundation for constructing V-nets in subsequent steps.

STEP 2: EVENT TYPE DETERMINATION

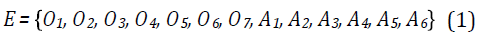

In Step 2, events are curated and classified into three main types: alarms, operational actions, and critical conditions. Let E be the set of all event types such that:

where A represents alarms, O denotes operational actions, and C indicates critical conditions. Each event type e ∈ E is characterized by specific thresholds, triggers, and criteria defined through functions T(e) that map conditions to events:

where ti, are the thresholds or conditions associated to each event. Alarms A signal deviations from predefined thresholds, while operational actions O and critical conditions C are linked to maintaining process integrity and responding swiftly to hazardous situations, respectively. This classification process, driven by HAZOP insights, ensures that the selection and prioritization of event types are aligned with the operational realities of the plant.

STEP 3: EVENT SEQUENCE GENERATION

Step 3 involves generating event sequences to represent a range of operational scenarios, both normal and abnormal. Let S be the set of all possible sequences, where each sequence s is an ordered set of events:

with ei ∈ E. The sequences are constructed to simulate a variety of conditions, including routine operations, start-ups, shutdowns, malfunctions, and deviations. For each sequence s, a temporal function τ(ei, ej) defines the time interval between events ei and ej, capturing the temporal dependencies and the dynamic nature of the process. This step utilizes risk assessment matrices and probabilistic models to evaluate the severity and likelihood of each scenario, informing strategies for alarm prioritization and response planning.

STEP 4: V-NETS CONSTRUCTION AND ANALYSIS

In the final step, V-nets are constructed to model the interconnectedness and temporal dynamics of event sequences. A V-net can also be defined as a directed graph ∈ = (V, A), where V represents nodes corresponding to events, and A denotes edges that map temporal relationships and dependencies between events. Each edge (vi, vj) G E is associated to a set of constraints C(vi, vj) that define allowable temporal and causal sequences, represented mathematically as:

where τmin and τmax are the minimum and maximum allowable time intervals between events vi and vj. The V-net construction is validated through a sequence simulation process that tests vulnerabilities, inefficiencies, and potential alarm management failures. Optimization functions F(V) can be applied to refine alarm strategies and response plans:

F(V) = minimize ( Σ false positives + Σ response time deviations )

This optimization ensures that the V-net framework enhances the alarm management system's effectiveness, boosting safety, operational efficiency, and resilience.

4 EXPERIMENTAL DEVELOPMENT

In Colombia, a pioneering initiative by Ecopetrol and H2B2 has resulted in the establishment of the country's first two hydrogen stations, each one distinguished by unique attributes. The first station, located in Cartagena, is part of a sustainable mobility project designed to supply hydrogen to light and heavy vehicles. Equipped with the EL10N electrolyzer, it boasts a production capacity of 1 kg/h. Meanwhile, the second hydrogen station, situated in Bogota and serving a similar purpose, uses the EL30N electrolyzer to produce an impressive 3 kg/h of renewable hydrogen. The EL30N Green Hydrogen electrolyzer, a flagship technology from H2B2, represents an advanced, high-capacity solution for hydrogen production. Employing Proton Exchange Membrane (PEM) electrolysis technology, it ensures caustic-free operation. This single-cell stack plant exhibits a robust hydrogen production capability, with a maximum nominal flow of 31.7 Nm3/h (equivalent to 68.40 kg/ day). The plant's flexibility is noteworthy, spanning hydrogen flow rates from 10% to 100%, all within an operating pressure range of 15 to 40 barg (217-580 psig). Hydrogen purity is a key feature, exceeding 99.9% before gas purification, with oxygen levels below 25 ppm and minimal water vapor saturation. Post-gas purification, the purity reaches an impressive 99.999%, while oxygen and water content remain below 5 ppm. The EL30N plant accommodates various voltage options, operates at either 50 Hz ± 5% or 60 Hz ± 3%, and requires a total power of 164.8 KW (including Balance of Plant and Stack). Stack consumption is measured at 4.7 KWh/Nm3H2, maintaining energy efficiency with an AC power consumption of 5.2 KWh/Nm3H2. Water consumption is minimal (< 1 liter per Nm3H2), and the plant adheres to stringent water quality parameters for high conductivity and low Total Organic Carbon (TOC) levels. The plant's control system features a fully automated PLC and a 15" color touchscreen interface, with communication options including Modbus TCP/IP or Profinet protocols. Environmental considerations are paramount, with the plant designed to operate within an ambient temperature range of +5 °C to +45 °C (+41 °F to +113 °F), suitable for indoor and outdoor installations. Safety features, including an uninterruptible power supply (UPS), overpressure relief, and an emergency shutdown system, ensure operational integrity. The plant's design underscores adaptability and scalability, fitting into a 20 ft container, and weighing approximately 11,000 Kg. It complies with CE, ISO 22734-1, NFPA 2-2016, and NFPA 70 standards, affirming its adherence to rigorous quality and safety requirements. Additional characteristics, such as a duty cycle of 100%, rapid start-up times, and provisions for Nitrogen Supply and Instrumentation Air Systems, enhance its operational efficiency. The Electrolysis Technologies H2B2 reference EL30N Green Hydrogen plant represents a convergence of innovative technology, high performance, and a steadfast commitment to advancing the green hydrogen production landscape. The forthcoming implementation of the VBAM methodology in the subsequent subsections is poised to provide theoretical insights into a case study involving a typical GHP startup.

STEP 1: PRELIMINARY HAZARD ANALYSIS

The EL30N Green Hydrogen Plant, employing Proton Exchange Membrane (PEM) electrolysis technology, is intended to produce hydrogen gas through an efficient and sustainable process. Prioritizing the safety and reliability of plant operations, an extensive Preliminary Hazard and Operability Analysis (HAZOP) has been conducted. This analysis, specifically targeting potential hazards and vulnerabilities associated to an abnormal startup scenario, seeks to identify critical operational actions and corresponding alarms. The ultimate goal is to proactively address risks and enhance safety measures during the plant's startup phase. The HAZOP conducted for the EL30N Green Hydrogen Plant has brought to light several critical situations requiring focused attention, plus the implementation of mitigation strategies to ensure operational safety and reliability. Among the identified scenarios, some of the most critical situations demanding careful consideration include:

Electrolyte Contamination Hazard: The analysis underscores the potential hazard linked to electrolyte contamination. Inadequate or contaminated electrolytes may compromise the performance of the electrolysis stack, resulting in reduced efficiency or even stack damage. Rigorous quality control and monitoring procedures for electrolyte preparation and injection are deemed essential. Regular analysis and testing of electrolyte composition serve as preventive measures, ensuring the integrity of the stack and the overall hydrogen production process.

Hydrogen Leak Risk during Gas Flow Initiation: The initiation of a hydrogen gas flow during the startup process poses a critical situation with the risk of a potential hydrogen gas leak. Such a leak could present a significant flammable hazard, jeopardizing the safety of personnel and equipment. Mitigation strategies include robust leak detection systems, proper ventilation, and well-established emergency shutdown procedures. Adequate personnel training in leak response protocols is imperative for swift and effective action in the event of a hydrogen leak.

Stack Overtemperature Hazard: The risk of stack overtemperature emerges as a critical situation requiring vigilant monitoring and control. Failure to regulate stack temperature within the optimal range may result in overheating, potentially causing damage to stack components and disrupting hydrogen production. Implementing advanced temperature monitoring systems and automated control mechanisms can prevent this hazard. Additionally, clear temperature escalation protocols and emergency shutdown procedures must be in place to promptly address abnormal temperature fluctuations.

Power Supply Failure: The potential for power supply failure, particularly during critical startup stages, is a critical situation that could disrupt the hydrogen production process. To mitigate this risk, redundant power supply systems, uninterruptible power supply (UPS) units, and effective backup procedures must be in place. Regular maintenance and testing of power supply components are essential to ensure reliability and minimize the risk of power-related failures.

In sum, the HAZOP analysis conducted for the EL30N Green Hydrogen Plant has pinpointed critical scenarios that demand proactive interventions to enhance safety and operational integrity. Implementing robust protocols, advanced monitoring systems, comprehensive training, and well-defined response plans will be instrumental in securing the plant's successful and secure operation, contributing significantly to the progress of sustainable and efficient hydrogen production. During a standard startup, a sequence of discrete events is meticulously executed to initiate hydrogen production. The following operational actions and discrete events have undergone scrutiny in the HAZOP analysis:

Power Supply Initialization (Operational Action): Operators initiate the power supply to the electrolysis stack, providing the necessary energy for of the startup of the hydrogen production process.

Electrolyte Injection (Discrete Event): As an integral part of the startup sequence, electrolyte injection commences, facilitating the establishment of a stable electro-chemical environment within the PEM electrolysis stack.

Hydrogen Gas Flow Initiation (Operational Action): Following confirmation of stack stability, operators initiate the flow of hydrogen gas, gradually increasing the flow rate to the desired operational level.

Gas Purity Monitoring (Discrete Event): Throughout the startup phase, continuous monitoring of gas purity levels ensures compliance with specified purity standards. Deviations trigger immediate corrective actions.

Stack Temperature Stabilization (Operational Action): Operators vigilantly monitor and control stack temperature, ensuring it remains within the optimal range for efficient hydrogen gas production.

Hydrogen Flow Adjustment (Discrete Event): Progressing through the startup, the hydrogen flow rate is adjusted as necessary to achieve the targeted production output.

Alarms and Potential Hazards in Startup Operations: The operational actions and discrete events identified in the startup sequence of the EL30N Green Hydrogen Plant entail specific alarms and potential hazards:

Power Supply Failure Alarm: A power supply failure during startup has the potential to disrupt the process and jeopardize the stability of the electrolysis stack.

Electrolyte Contamination Hazard: Inadequate or contaminated electrolytes pose a risk to stack performance, potentially resulting in reduced efficiency or damage to the stack.

Hydrogen Leak Hazard: The initiation of hydrogen gas flow brings the risk of a hydrogen gas leak, presenting a flammable hazard that necessitates immediate shutdown and evacuation procedures.

Gas Purity Deviation Alarm: Deviations from specified gas purity levels may indicate equipment malfunction or abnormal chemical reactions within the stack.

Stack Overtemperature Hazard: Failure to control stack temperature could lead to overheating, posing a risk of damage to stack components.

Inadequate Hydrogen Flow Alarm: Insufficient adjustment of hydrogen flow could lead to lower production rates, adversely affecting overall plant efficiency.

The Preliminary Hazard and Operability Analysis (HAZOP) conducted for the normal startup scenario of the EL30N Green Hydrogen Plant have identified these operational actions, discrete events, associated alarms, and potential hazards. Proactively addressing these aspects enables the plant's operational team to implement safety measures and response protocols, ensuring a smooth and secure startup process. This comprehensive analysis contributes greatly to the overall safety and success of hydrogen production operations at the EL30N Green Hydrogen Plant within the framework of sustainable energy generation.

STEP 2: EVENT TYPE DETERMINATION

For normal or abnormal startups, the following event types were identified.

Power Supply Initialization (Operational Action): O1

Electrolyte Injection (Discrete Event): O2

Hydrogen Gas Flow Initiation (Operational Action): O3

Gas Purity Monitoring (Discrete Event): O4

Stack Temperature Stabilization (Operational Action): O5

Hydrogen Flow Adjustment (Discrete Event): O6

Reporting final startup (Discrete Event): O7

Power Supply Failure Alarm: A1

Electrolyte Contamination Hazard: A2

Hydrogen Leak Hazard: A3

Gas Purity Deviation Alarm: A4

Stack Overtemperature Hazard: A5

Inadequate Hydrogen Flow Alarm: A6

Therefore, the set of event types that can occur in a normal or abnormal startup is defined as a set E in which:

As it will be outlined in the next step, the possible simultaneous situations that could occur and that represent an abnormal and critical behaviour in the startup can be defined as:

Β* corresponds to the simultaneous occurrence of O1 and A1.

µ* corresponds to the simultaneous occurrence of O2 and A2.

Π* corresponds to the simultaneous occurrence of O3 and A3.

σ* corresponds to the simultaneous occurrence of O4 and A4.

η* corresponds to the simultaneous occurrence of O5 and A5.

Therefore, the events from which timed observations are taken are given by:

STEP 3: EVENT SEQUENCE GENERATION

In the initiation sequence of the EL30N Green Hydrogen Plant, a meticulously coordinated arrangement of events is essential to guarantee a seamless and secure startup process. Each event type has a designated role, and their timing must comply with specific constraints to uphold operational integrity. Following the initiation of Power Supply (O1), the Electrolyte Injection (O2) event must take place within 1 to 2-time units. This prompt action ensures that the electrolysis stack is properly prepared for hydrogen generation. Subsequently, within the time limit of 2 to 3-time units after electrolyte injection, the Hydrogen Gas Flow Initiation (O3) event occurs. This step marks the beginning of hydrogen production, and sets the stage for subsequent processes. Concurrently with hydrogen gas flow initiation, Gas Purity Monitoring (O4) is activated within a window of 1 to 2-time units. This event verifies the quality of produced hydrogen, ensuring it meets stringent purity standards. The time restriction of 1 to 2-time units ensures that gas purity is monitored promptly after hydrogen flow initiation. Once the hydrogen gas flow is established, Stack Temperature Stabilization (O5) becomes imperative. This operational action is executed within 2 to 3-time units after gas flow initiation. Proper stack temperature control is vital for efficient and safe hydrogen production. Following stack temperature stabilization, Hydrogen Flow Adjustment (O6) occurs within 1 to 2 time units. This event allows for fine-tuning of hydrogen production, ensuring optimal flow rates are achieved for the subsequent stages. Throughout the startup process, continuous monitoring of critical parameters is essential. The Power Supply Failure Alarm (A1) is activated within 1 to 2-time units to promptly detect any power supply issues that may arise. After Electrolyte Injection (O2), the system monitors Electrolyte Contamination Hazard (A2) within 2 to 3 time units. This event detects any contamination in the electrolyte, triggering the necessary safety measures. Similarly, as hydrogen gas flow is established, continuous monitoring for Hydrogen Leak Hazard (A3) occurs within 2 to 3-time units. This alarm ensures that any potential leaks are detected and addressed promptly. Concurrently with Gas Purity Monitoring (O4), the system also watches for Gas Purity Deviation Alarm (A4), which activates within 1 to 2-time units in case of any deviations from the specified purity levels. During Stack Temperature Stabilization (O5), the system monitors for Stack Overtemperature Hazard (A5), triggering an alarm within 2 to 3-time units if the stack temperature exceeds safe limits. Lastly, after Hydrogen Flow Adjustment (O6), the Inadequate Hydrogen Flow Alarm (A6) is activated within 1 to 2-time units if the hydrogen flow rate is insufficient. The meticulous timing of these events and the corresponding alarms guarantees a systematically organized and secure startup process for the EL30N Green Hydrogen Plant. Adherence to these precise time restrictions acts as a protective measure against potential hazards and deviations, allowing for an efficient and reliable production of hydrogen.

This startup sequence, governed by time restrictions, underscores the intricate relationship between operational actions and alarms, ensuring a regulated and secure hydrogen production process. The specified time constraints establish a framework for swift detection and response to potential issues, thereby enhancing the overall dependability and efficiency of the EL30N Green Hydrogen Plant. Within the operational framework of the EL30N Green Hydrogen Plant, a detailed sequence of events choreographs a methodical and secure startup process. Comprising a fusion of operational actions and alarms, this sequence is indispensable for a reliable, efficient initiation of hydrogen production. Noteworthy is the inherent interdependence of certain event types, underscoring the need for a well-defined temporal order to ensure safety and optimal system performance. The startup sequence begins with the critical step of Power Supply Initialization (O1), establishing the foundation for subsequent actions. Next, Electrolyte Injection (02) is enabled to facilitate the hydrogen production process. Once the electrolyte is in place, Hydrogen Gas Flow Initiation (03) occurs, setting the stage for controlled hydrogen generation. As hydrogen production commences, Gas Purity Monitoring (04) ensures adherence to specified purity levels. Subsequently, Stack Temperature Stabilization (O5) safeguards against potential overtemperature conditions, contributing to the system's longevity. Notably, each of these operational actions can only occur once, ensuring a systematic and controlled progression. Similarly, distinct hazard alarms are intricately woven into a sequence.

Power Supply Failure Alarm (A1) stands ready to swiftly alert to any power-related disruptions, while Electrolyte Contamination Hazard (A2) remains vigilant for any signs of electrolyte impurity. Hydrogen Leak Hazard (A3) watches potential leaks, and Gas Purity Deviation Alarm (A4) provides real-time monitoring against any deviations in gas purity. Stack Overtemperature Hazard (A5) and Inadequate Hydrogen Flow Alarm (A6) complete the safety net by guarding against excessive temperatures and inadequate flow. This intricately choreographed startup sequence underscores the paramount importance of a methodical approach in the EL30N Green Hydrogen Plant. The seamless interaction of operational actions and alarms, meticulously designed to avoid simultaneous occurrences and prevent redundancy, ensures establishing proof a safe, efficient, and optimized hydrogen production process. In addition, based on the characteristics of the EL30N Green Hydrogen Plant and the event types, we can determine what events cannot occur simultaneously and those that cannot occur more than once in the event sequence for a normal startup.

The occurrence of alarms, particularly during startup phases, is a routine aspect that should be expected. However, within the prescribed methodology for initiating the EL30N Green Hydrogen Plant, it is crucial to dispel a potential misconception regarding the timing of alarm generation. The statement suggesting that alarms are generated after a specific time following an operational event might be misunderstood. It should be clearly emphasized that alarms are typically triggered by unexpected events, often asynchronous failures, which can occur at any time. While the identification of certain failures may be linked to specific operational phases, asserting that alarms are generated after a fixed time is misleading. The specified timing is associated with periodic monitoring intervals or assessment points designed to systematically detect potential issues. This distinction is vital to convey that alarms respond to the identification of anomalies during scheduled monitoring periods, reflecting the systematic evaluation of system parameters rather than indicating a delayed reaction to an operational event. This clarification aims to ensure a precise understanding of the alarm management process embedded within the proposed methodology. Additionally, events that cannot occur simultaneously and events that cannot occur more than once are explained below for further clarity .

Power Supply Initialization (O1) and Power Supply Failure Alarm (A1): These two events cannot occur simultaneously, as the power supply must be successfully initialized before the system can detect a power supply failure.

Electrolyte Injection (O2) and Electrolyte Contamination Hazard (A2): These events cannot occur simultaneously, as electrolyte injection is a pre-requisite process before contamination can be detected.

Hydrogen Gas Flow Initiation (O3) and Hydrogen Leak Hazard (A3): These events cannot occur simultaneously, as gas flow must be initiated before any potential leaks can be detected.

Gas Purity Monitoring (O4) and Gas Purity Deviation Alarm (A4): These events cannot occur simultaneously, as gas purity monitoring is necessary to detect any deviations from the specified purity levels.

Stack Temperature Stabilization (O5) and Stack Overtemperature Hazard (A5): These events cannot occur simultaneously, as stack temperature stabilization must be achieved before overtemperature conditions can be monitored.

Power Supply Initialization (O1), Electrolyte Injection (O2), Hydrogen Gas Flow Initiation (O3), Gas Purity Monitoring (O4), Stack Temperature Stabilization (O5), and Hydrogen Flow Adjustment (O6): These operational actions can only occur once during the startup sequence, as they are part of the initial process setup.

Power Supply Failure Alarm (A1), Electrolyte Contamination Hazard (A2), Hydrogen Leak Hazard (A3), Gas Purity Deviation Alarm (A4), Stack Overtemperature Hazard (A5), and Inadequate Hydrogen Flow Alarm (A6): These alarms are triggered by specific conditions and cannot occur more than once during the startup sequence, as they indicate distinct issues.

An effective startup event sequence establishes a regulated and secure startup process by outlining the temporal relationships and constraints among event types in the EL30N Green Hydrogen Plant. In the meticulously coordinated startup sequence of the EL30N Green Hydrogen Plant, the adherence to time restrictions is crucial for upholding the integrity and safety of the hydrogen production process. The timing of each event is precisely calibrated to facilitate the seamless progression of operations and mitigate potential hazards. Any deviations from these time restrictions have the potential to introduce inefficiencies, safety risks, and operational disruptions. One critical violation of time restriction could involve the Electrolyte Injection (O2) occurring later than expected after the Power Supply Initialization (O1). This delay could hinder the timely establishment of the electrolytic process, potentially leading to extended startup times and reduced efficiency. The Electrolyte Injection serves as a foundation for subsequent actions, and any delay in this step might ripple through the sequence, affecting the entire startup process. Additionally, a delay in the activation of the Stack Temperature Stabilization (O5) following the Gas Purity Monitoring (O4) could compromise the stack's thermal equilibrium. Timely temperature stabilization is crucial for preventing stack overtemperature hazards (A5) that could lead to degradation and safety concerns. Through strict adherence to the specified time restrictions, the EL30N Green Hydrogen Plant guarantees the orderly occurrence of each event, thereby minimizing the potential for inefficiencies and safety hazards. The reliability of the startup sequence relies heavily on these exact timing considerations, emphasizing their crucial role in ensuring the dependable and secure operation of the hydrogen production process.

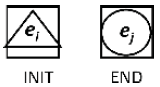

STEP 4: V-NETS CONSTRUCTION

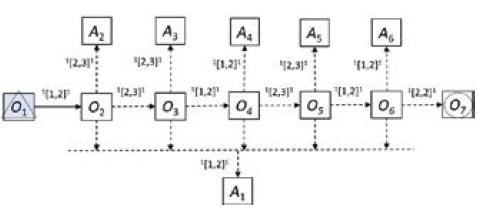

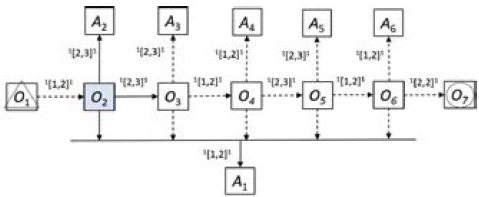

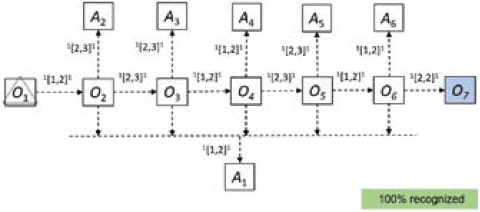

In the development of V-nets, a systematic approach is employed to capture the intricate dynamics inherent in event sequences within a given process. The initial phase involves identifying the initial and terminal event types within the sequence, delineating the commencement and conclusion of the V-net and establishing a clear boundary for subsequent analysis. Once these starting and ending points are defined, the construction of the V-net commences by linking the initial event to the subsequent occurrence of the next event type. This linkage is formed through a directed arc, symbolizing the temporal relationship between these events. Crucially, each arc's associated time interval not only represents the duration between events but also acts as an indicator of the frequency of occurrence for each event type. This time interval encapsulates the transition time between states, reflecting the natural progression of the process and highlighting temporal dependencies between events. This dynamic temporal framework provides a visual representation of the unfolding events over time, offering valuable insights into the evolution of the sequence. As the V-net is systematically built, interconnecting each event with its subsequent occurrence, a comprehensive network of events emerges. This network inherently captures the causal relationships and temporal dynamics governing the process, forming a digital model that not only represents the sequence but also embodies their interplay, timing, and frequency. Essentially, V-net construction amalgamates the chronological order of events, their temporal relationships, and recurring patterns. This methodology not only aids in understanding event progression within a process but also facilitates the identification of potential bottlenecks, inefficiencies, and optimization opportunities. By visually mapping the event sequence with associated time intervals, the V-net methodology becomes a potent tool for enhancing operational insights and refining alarm management strategies, as delineated in [7, 8]. Constructing the V-net for a normal startup, where ξ = {O1, O2, O3, O4, O5, O6, O7, A1, A2, A3, A4, A5, A6}, see Fig. 2.

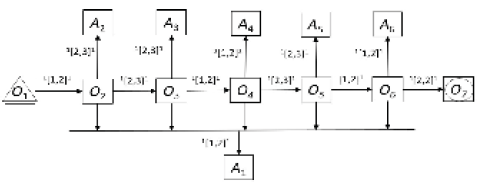

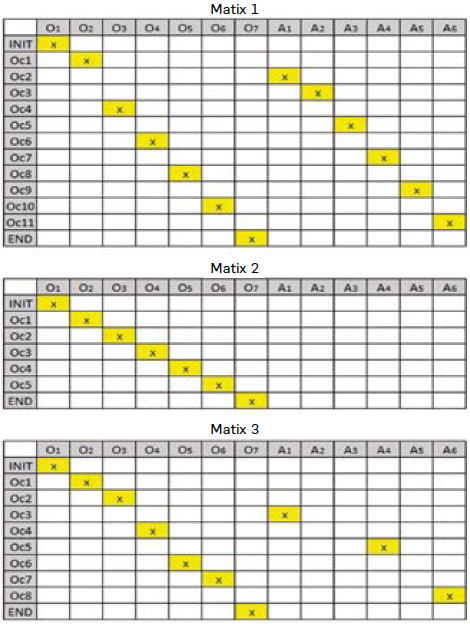

From the total occurrence matrices, Fig. 3 shows three possible occurrence matrices in the startup of this GHP. Matrix 1 indicates the activation of all the alarms in a normal startup, in Matrix 2 no alarm is activated, and in Matrix 3 some alarms in this case A1, A4, and A6 are activated. Worth noting that these event sequences could be assumed as possible for a normal startup in a GHP.

5. RESULTS

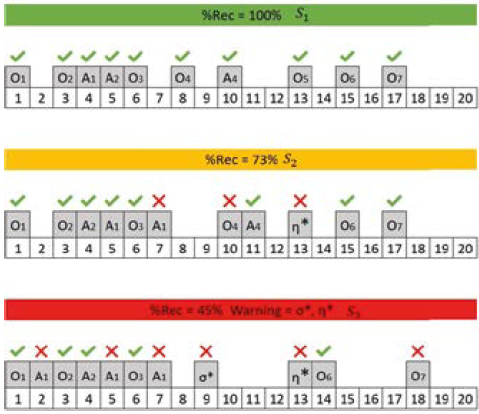

Three evaluation event sequences were used to test the V-net, and the results are exposed in Fig. 4. The first event sequence corresponds to S1. These data come from the process, which recognizes the V-net as a good trace in 100%. In Fig. 5, the first timed observation is (O1,1) where the commencement of the startup journey is marked by the Power Supply Initialization (O1) event, and it activates the time restriction O1[1, 2]O2 waiting for the next event occurrence that is O2. Now, after 2-time units, the Electrolyte Injection event ensues at (O2,3), satisfying the time restriction, and securing the optimal preparation of the electrolysis stack for efficient hydrogen generation, and activating the next time restrictions for the possible occurrence of A1, O3 or A2, see Fig. 6. Fig. 7 the final event O7 recognizes this V-net at 100%.

In this example, the sequence of events S2 is recognized in 73%. as Alike S1, this sequence represents the data derived from the process, and oit can be noted that the time observation (A1,7) does not satisfy the condition of the frequency of occurrence for A1, which must occur only once in the event sequence for a normal startup. Then, the time observation (O4,10) does not satisfy the time restriction O3[1, 2]O4 because O4 occurs too late. Lastly, a warning is generated by the simultaneous occurrence of O5 and A5 occurring at (η*,13). The last sequence of events analyzed is S3, which was recognized at 45%; in this sequence of events it is observe that the event (A1,2) does not satisfy the condition of activation of the time restriction as this alarm only occurs after O2, although (A1,5) complies with the time restriction, but its frequency does not, which is also the case in (A1,7). Further, it had two warnings: Warning: σ* and Warning: η* at (σ*, 9), and (η*, 13). Finally, (O7, 18) it does not meet its time constraints.

In sum, the application of V-nets in the evaluation of event sequences is a powerful tool for enhancing the operational efficiency and safety of processes, such as those in the context of the EL30N Green Hydrogen Plant. By analyzing the results shown in Fig. 4, we gain valuable insights into how V-nets can assist operators and decision-makers at Ecopetrol. In the first event sequence, denoted as S1, the V-net successfully recognizes the sequence as a good trace with a 100% match to the process data. This evidences the V-net's capability to accurately capture and validate sequences adhering to expected patterns of behavior. This aspect is particularly valuable to Ecopetrol operators, as it provides a reliable means of confirming that the startup process is unfolding as intended, instilling confidence in the operational sequence. Moving to the sequence S2, although it is recognized at a slightly lower confidence level below 73%, the V-net still demonstrates its ability to identify patterns and deviations within the operational sequence. The specific instance of time observation (A1,7), which does not align with the required frequency of occurrence, highlights how V-nets can act as a proactive alert system. By detecting such discrepancies, the V-net helps Ecopetrol operators to quickly address anomalies and ensure that critical steps are executed in the correct order and timing. Furthermore, the identification of warnings, such as the simultaneous occurrence of O5 and A5 at (η* ,13), showcases the V-net's capacity to pinpoint potential hazards or non-optimal situations. This empowers operators to take corrective actions in a timely manner, thus preventing adverse outcomes and improving overall process safety. In the case of the event sequence S3, the V-net's recognition at 45% indicates its ability to provide insights even when the sequence deviates from the expected behavior. The detection of time-restrictions violations and frequency deviations, as well as the generation of warnings, underscores how V-nets serve as a valuable decision-support tool. Ecopetrol operators can leverage this information to fine-tune their operational procedures, ensuring that alarms, actions, and events occur within the desired sequence and timeframe. The utilization of V-nets offers Ecopetrol operators a comprehensive framework for monitoring, analyzing, and optimizing the startup process of the EL30N Green Hydrogen Plant. By proactively identifying deviations, ensuring proper sequencing, and generating alerts for potential problems, V-nets contribute to the enhancement of operational efficiency, safety, and reliability, ultimately driving the plant's success relative to green hydrogen production.

As for tackling the intricacies of complex systems, particularly those involving numerous events such as 13 in this scenario, the V-net methodology requires a comprehensive approach. First, one must systematically calculate the permutations of events to grasp the sequential possibilities, laying a foundation to understand the system's dynamic behavior. However, the challenge intensifies when considering variations in time constraints. Each event's occurrence at different points within the time restrictions, whether at the low limit, high limit, or middle limit, introduces additional complexity by exploring temporal dependencies and their impact. To manage the potential combinatorial explosion resulting from the diverse interplay of events, a strategic approach is crucial. Instead of an exhaustive analysis, prioritizing critical paths or scenarios that are likely to profoundly influence system behavior can streamline the investigation. Automation and simulation tools play an important role in handling complexity. Automated algorithms facilitate the exploration of various event sequences, while simulation techniques provide a virtual environment to observe how the system responds to different conditions.

Recognizing patterns within sequences and generalizing their impact aid in simplifying the analysis. This involves understanding how certain types of events interact and influence the overall system. Risk-driven prioritization is essential, as not all event combinations pose equal risks. By prioritizing the analysis based on factors such as severity, likelihood, or criticality, the methodology can focus its attention on the most significant aspects. An iterative refinement process is inherent in dealing with complexity. Initial analyses guide the identification of key scenarios, and subsequent iterations allow for a deeper dive into specific aspects or the refinement of the analysis based on emerging insights. Considering dependencies between events is crucial. Some events may be contingent on others, and understanding these dependencies refines the analysis of possible sequences. Calculating the exact number of possible event sequences involves permutations, typically denoted as n! (n factorial), where n is the number of event types. For 13 events, it would be 13!. However, this calculation must be adjusted based on considerations of time constraints, dependencies, and variations in event occurrences, making it a complex ,although essential, computation for a comprehensive V-net analysis.

CONCLUSIONS

In sum, the implementation of V-nets-based alarm management is a transformative approach for elevating the oversight and functioning of green hydrogen plants, exemplified in our study focusing on the EL30N Green Hydrogen Plant. The systematic integration of V-nets facilitates a comprehensive analysis of event sequences, providing valuable insights into the timing, frequency, and interdependencies of crucial operational actions and alarms. This innovative methodology provides the operators and decision-makers with a proactive tool that ensures adherence to proper sequences while swiftly identifying deviations, hazards, and potential inefficiencies. The successful application of V-nets in EL30N startup sequences showcases their capacity to enhance operational integrity, safety measures, and efficiency optimization. By pinpointing critical time restrictions, frequency violations, and warnings, V-nets enable Ecopetrol operators to make informed decisions, take preventive actions, and streamline their processes. This results in a more robust startup process, reduced downtime, and improved production outcomes, aligned with the broader goals of green hydrogen plant operations and the transition to sustainable energy solutions. The orchestrated synchronization of alarms with operational events contributes to optimized system response, preventive monitoring, efficient troubleshooting, enhanced safety measures, and improved operational efficiency. The methodical sequencing of events and alarms adds a layer of precision, minimizing the risk of conflicts and enhancing the overall reliability of hydrogen production. The temporal constraints play a pivotal role in aligning alarms with the dynamic progression of events, offering an advanced framework for alarm supervision in industrial processes.

Looking ahead, there are several avenues for further exploration in this field. Extending the application of V-nets to other operational phases beyond startup, such as shutdown or maintenance procedures, could provide a comprehensive framework for holistic process optimization. Additionally, incorporating real-time data streams and advanced predictive analytics can further enhance the V-net's capabilities for anomaly detection and performance prediction. Exploring the integration of artificial intelligence and machine learning techniques to enhance V-net accuracy and decision support is a promising avenue for research. In sum, the V-nets-based alarm management methodology offers a promising trajectory for enhancing green hydrogen plant supervision, emphasizing its potential to revolutionize not only startup procedures but also the broader operational landscape. By harnessing the power of V-nets, the journey toward safe, efficient, and sustainable green hydrogen production takes a significant step forward, with promising opportunities for continued advancements in the field.

REFERENCES

- Ajanovic, A., Sayer, M., & Haas, R. (2024). On the future relevance of green hydrogen in Europe. Applied Energy, 358, 122586. https://doi.org/10.1016/j.apenergy.2023.122586

» https://doi.org/10.1016/j.apenergy.2023.122586 - Capacho, J. V., Subias, A., Trave-Massuyes, L., & Jimenez, F. (2017). Alarm management via temporal pattern learning. Engineering Applications of Artificial Intelligence, 65, 506-516. https://doi.org/10.1016/j.engappai.2017.07.008

» https://doi.org/10.1016/j.engappai.2017.07.008 - Capacho, J. W. V., Zuñiga, C. G. P., Maldonado, Y. A. M., & Castro, A. O. (2020). Simultaneous occurrences and false-positives analysis in discrete event dynamic systems. Journal of Computational Science, 44, 101162. https://doi.org/10.1016/j.jocs.2020.101162

» https://doi.org/10.1016/j.jocs.2020.101162 - Cong, L., Yang, J., Shi, L., Zhou, X., Liu, L., Jiang, F., & Zhang, A. (2023). Intelligent operation and maintenance business process optimization design of integrated energy system. In 2023 5th Asia Energy and Electrical Engineering Symposium (AEEES), IEEE, 1741-1746. https://doi.org/10.1109/AEEES56888.2023.10114192

» https://doi.org/10.1109/AEEES56888.2023.10114192 - Fanti, M. P., Mininel, S., Ukovich, W., & Vatta, F. (2012). Modelling alarm management workflow in healthcare according to IHE framework by coloured Petri nets. Engineering Applications of Artificial Intelligence, 25(4), 728-733. https://doi.org/10.1016/j.engappai.2010.11.003

» https://doi.org/10.1016/j.engappai.2010.11.003 - Feng, L., Gu, Y., Pang, J., Jiang, L., Liu, J., Zhou, H., & Babaee, S. (2024). Risk identification and safety technology for hydrogen production from natural gas reforming. ChemBioEng Reviews, 11(2), 386-405. https://doi.org/10.1002/cben.202300049

» https://doi.org/10.1002/cben.202300049 - Görgülü, H., & Özkasap, Ö. (2023, July). Machine Learning Methods for Alarm Prediction in Industrial Informatics: Review and Benchmark. In International Symposium on Distributed Computing and Artificial Intelligence (pp. 21-30). Cham: Springer Nature Switzerland. https://doi.org/10.1007/978-3-031-38616-9_3

» https://doi.org/10.1007/978-3-031-38616-9_3 - International Energy Agency (IEA 50). (June 2019). The future of hydrogen. Tech. rep. Paris. https://www.iea.org/reports/the-future-of-hydrogen

» https://www.iea.org/reports/the-future-of-hydrogen - Jansons, L., Zemite, L., Zeltins, N., Bode, I., Geipele, I., & Kiesners, K. (2022). The green hydrogen and the EU gaseous fuel diversification risks. Latvian Journal of Physics and Technical Sciences, 59(4), 53-70. https://doi.org/10.2478/lpts-2022-0033

» https://doi.org/10.2478/lpts-2022-0033 - Jin, H., Gao, Z., Zuo, Z., Zhang, Z., Wang, Y., & Zhang, A. (2023). A combined model-based and data-driven fault diagnosis scheme for lithium-ion batteries. IEEE Transactions on Industrial Electronics https://ieeexplore.ieee.org/document/10203013

» https://ieeexplore.ieee.org/document/10203013 - Kovač, A., Paranos, M., & Marcius, D. (2021). Hydrogen in energy transition: A review. International Journal of Hydrogen Energy, 46(16), 10016-10035. https://doi.org/10.1016/j.ijhydene.2020.11.256

» https://doi.org/10.1016/j.ijhydene.2020.11.256 - Kumar, S., Arzaghi, E., Baalisampang, T., Garaniya, V., & Abbassi, R. (2023). Insights into decision-making for offshore green hydrogen infrastructure developments. Process Safety and Environmental Protection, 174, 805817. https://doi.org/10.1016/j.psep.2023.04.042

» https://doi.org/10.1016/j.psep.2023.04.042 - Kumar, S., Baalisampang, T., Arzaghi, E., Garaniya, V., Abbassi, R., & Salehi, F. (2023). Synergy of green hydrogen sector with offshore industries: Opportunities and challenges for a safe and sustainable hydrogen economy. Journal of Cleaner Production, 384, 135545. https://doi.org/10.1016/j.jclepro.2022.135545

» https://doi.org/10.1016/j.jclepro.2022.135545 - Ni, C., & Li, S. C. (2024). Machine learning enabled industrial IoT security: Challenges, trends, and solutions. Journal of Industrial Information Integration, 100549. https://doi.org/10.1016/j.jii.2023.100549

» https://doi.org/10.1016/j.jii.2023.100549 - Noussan, M., Raimondi, P. P., Scita, R., & Hafner, M. (2020). The role of green and blue hydrogen in the energy transition-A technological and geopolitical perspective. Sustainability, 13(1), 298. https://doi.org/10.3390/su13010298

» https://doi.org/10.3390/su13010298 - NTRS-NASA. Technical Reports Server (January 1997). Safety standard for hydrogen and hydrogen systems: Guidelines for hydrogen system design, materials selection, operations, storage and transportation. (TM) NASA-TM-112540. https://ntrs.nasa.gov/citations/19970033338

» https://ntrs.nasa.gov/citations/19970033338 - Rajapriya, R., & Dangate, M. S. (2023). Hydrogen as a fuel cell. Integrated Green Energy Solutions, 1, 45-59. https://doi.org/10.1002/9781119847564.ch4

» https://doi.org/10.1002/9781119847564.ch4 - Scheller, F., Wald, S., Kondziella, H., Gunkel, P. A., & Bruckner, T. (2023). Future role and economic benefits of hydrogen and synthetic energy carriers in Germany: A review of long-term energy scenarios. Sustainable Energy Technologies and Assessments, 56, 103037. https://doi.org/10.1016/j.seta.2023.103037

» https://doi.org/10.1016/j.seta.2023.103037 - Shein, G. S., Brodie, R., & Mintz, Y. (2023). Human-Machine Collaboration in AI-Assisted Surgery: Balancing Autonomy and Expertise. Artificial Intelligence in Medicine and Surgery-An Exploration of Current Trends, Potential Opportunities, and Evolving Threats-Volume 1 https://www.intechopen.com/chapters/87002

» https://www.intechopen.com/chapters/87002 - Superchi, F., Mati, A., Carcasci, C., & Bianchini, A. (2023). Techno-economic analysis of wind-powered green hydrogen production to facilitate the decarbonization of hard-to-abate sectors: A case study on steelmaking. Applied Energy, 342, 121198. https://doi.org/10.1016/j.apenergy.2023.121198

» https://doi.org/10.1016/j.apenergy.2023.121198 - Vasquez Capacho, J. W., Perez Zuñiga, C. G., Muñoz Maldonado, Y. A., & Ospino Castro, A. J. (2020, June 30). An additional layer of protection through superalarms with diagnosis capability. CT&F - Ciencia, Tecnología y Futuro, 10(1), 45-66. https://doi.org/10.29047/01225383.168

» https://doi.org/10.29047/01225383.168 - Vasquez, J. W., Travé-Massuyès, L., Subias, A., Jiménez, F., & Agudelo, C. (2015, August). Chronicle based alarm management in startup and shutdown stages. In 26 th International Workshop on Principles of Diagnosis (pp. 277-280). https://ceur-ws.org/Vol-1507/dx15paper31.pdf

» https://ceur-ws.org/Vol-1507/dx15paper31.pdf - Zheng, W., Zheng, X., & Zhu, X. (2024). Promoting integration of industry and vocational education: Exploring stakeholder intentions of hydrogen energy industry. International Journal of Hydrogen Energy, 52, 454-464.. https://doi.org/10.1016/j.ijhydene.2023.06.072

» https://doi.org/10.1016/j.ijhydene.2023.06.072

AUTHORS

-

How to cite:

Vásquez et al., (2024). Enhancing Alarm Management in Green Hydrogen Plants: A Comprehensive Analysis of the V-nets-Based Methodology Plants. Ciencia, Tecnología y Futuro - CT&F. Vol. 14 No. 2, 15-28

Publication Dates

-

Date of issue

Jul-Dec 2024

History

-

Received

27 Nov 2023 -

Reviewed

24 Sept 2024 -

Accepted

27 Sept 2024