ABSTRACT

The environmental impactof fossil fuels and their limited availability increase the need for research into alternative energy sources. In this research, pyrolysis oil (PO) was obtained from waste sour cherry kernels. PO cannot be used directly as fuel in diesel engines because of its negative fuel properties, such as low energy density, high viscosity, high water content, and low cetane number. Therefore, PO was blended with diesel at various weight proportions (wt%) using n-butanol (NB) as co-solvent, and 2-ethylhexyl nitrate (2-EHN) as cetane improver. Blended fuels containing 40 wt% diesel i.e., D2 (Diesel 40% / PO 0% / NB 55% / 2-EHN %5), D3 (Diesel 40 / PO 5% / NB 50% / 2-EHN 5%) and D4 (Diesel 40% / PO 15% / NB 40% / 2-EHN 5%) were identified as optimal blend compositions regarding the physicochemical characteristics of fuel. These fuels were tested for engine performance and emission characteristics at engine speeds of 1500, 1800, 2400, 3000 and 3600 rpm under full engine load (10 Nm) in a single-cylinder diesel engine. All data (i.e. cylinder pressure, engine torque and performance changes, heat release rate, and emission characteristics) were recorded using a Kistler KiBox data acquisition system. The engine tests showed a decrease in NOx, HC and soot emissions when blended fuels (D2, D3 and D4) were compared to D1 (Diesel 100% / PO 0% / NB 0% / 2-EHN 0°%). The lower NOx emissions in the blended fuels are explained by the PO's water content. Water raises the specific heat capacity of the fuel-air mixture while reducing the internal cylinder temperature. Additionally, the high latent heat of evaporation of n-butanol may contribute to reduce NOx emissions. In addition, the decrease in HC emissions may be caused by the increase in the oxygen ratio of blended fuels, while the decrease in soot emissions may be caused by the low C/H ratio and high oxygen content of blended fuels. To conclude, blends of PO, diesel n-butanol, and 2-EHN can be used as biofuels in diesel engine applications.

KEYWORDS:

Alternative fuels; Pyrolysis oil; N-butanol; 2-ethylhexyl nitrate; Diesel engine; Emissions

RESUMEN

Los impactos ambientales de los combustibles fósiles y su disponibilidad limitada aumentan la necesidad de investigar fuentes de energía alternativas. En esta investigación, se obtuvo aceite de pirólisis (PO) a partir de residuos de huesos de cereza ácida. El PO no puede utilizarse directamente como combustible en motores diésel debido a sus propiedades negativas, como baja densidad de energía, alta viscosidad, alto contenido de agua y bajo número de cetano. Por lo tanto, el PO se mezcló con diésel en varias proporciones de peso (wt%) utilizando n-butanol (NB) como co-solvente y nitrato de 2-etilhexilo (2-EHN) como mejorador del cetano. Los combustibles mezclados que contienen 40 wt% de diésel, es decir, D2 (Diésel 40% / PO 0% / NB 55% / 2-EHN 5%), D3 (Diésel 40% / PO 5% / NB 50% / 2-EHN 5%) y D4 (Diésel 40% / PO 15% / NB 40% / 2-EHN 5%) fueron identificados como las composiciones óptimas de mezcla con respecto a las características fisicoquímicas del combustible. Estos combustibles se probaron para el rendimiento del motor y las características de emisión a velocidades del motor de 1500, 1800, 2400, 3000 y 3600 rpm bajo carga completa del motor (10 Nm) en un motor diésel de un solo cilindro. Todos los datos (es decir, presión en el cilindro, par motor y cambios en el rendimiento, tasa de liberación de calor y características de emisión) se registraron utilizando un sistema de adquisición de datos Kistler KiBox. Las pruebas del motor mostraron una disminución en las emisiones de NOx, HC y hollín cuando se compararon los combustibles mezclados (D2, D3 y D4) con D1 (Diésel 100% / PO 0% / NB 0% / 2-EHN 0%). Las menores emisiones de NOx en los combustibles mezclados se explican por el contenido de agua del PO. El agua aumenta la capacidad calorífica específica de la mezcla de aire-combustible mientras reduce la temperatura interna del cilindro. Además, el alto calor de evaporación del n-butanol puede contribuir a una reducción en las emisiones de NOx. Además, la disminución de las emisiones de HC puede ser causada por el aumento en la proporción de oxígeno de los combustibles mezclados, mientras que la disminución de las emisiones de hollín puede deberse a la baja proporción C/H y al alto contenido de oxígeno de los combustibles mezclados. En conclusión, las mezclas de PO, diésel, n-butanol y 2-EHN pueden ser utilizadas como biocombustibles en aplicaciones de motores diésel.

PALABRAS CLAVE:

Combustibles alternativos; Aceite de pirólisis; N-butanol; Nitrato de 2-etilhexilo; Motor diesel; Emisiones

1. INTRODUCTION

Because of the current decline in fossil fuel supplies, rising air pollution, and global warming, it is fascinating to consider using alternative fuels in place of fossil fuels. Therefore, it is very important to develop alternative fuels from biomass waste. Biomass waste is the source of pyrolysis oil (PO), a sustainable and clean energy (T. Bridgwater et al., 1999Bridgwater, A. V., Meier, D., & Radlein, D. (1999). An overview of fast pyrolysis of biomass. Organic geochemistry, 30(12), 1479-1493. https://doi.org/10.1016/S0146-6380(99)00120-5

https://doi.org/10.1016/S0146-6380(99)00...

; Bridgwater, 2012; Chong & Bridgwater, 2017Chong, K. J., & Bridgwater, A. V. (2017). Fast pyrolysis oil fuel blend for marine vessels. Environmental Progress & Sustainable Energy, 36(3), 677-684. https://doi.org/10.1002/ep.12402.

https://doi.org/10.1002/ep.12402...

; Zhang et al., 2007Zhang, Q., Chang, J., Wang, T., & Xu, Y. (2007). Review of biomass pyrolysis oil properties and upgrading research. Energy conversion and management, 48(1), 87-92. https://doi.org/10.1016/j.enconman.2006.05.010 , 25-31. https://doi.org/10.1111/gwmr.12349

https://doi.org/10.1016/j.enconman.2006....

). In recent studies, PO usage in internal combustion engines has gained importance (Barth & Kleinert, 2008Barth, T., & Kleinert, M. (2008). Motor fuels from biomass pyrolysis. Chemical Engineering & Technology: Industrial Chemistry-Plant Equipment-Process Engineering-Biotechnology, 31(5),773-781. https://doi.org/10.1002/ceat.200800122

https://doi.org/10.1002/ceat.200800122...

; Han et al., 2023Han, J., Somers, L. M. T., & van de Beld, B. (2023). Combustion and emission characteristics of hydrotreated pyrolysis oil on a heavy-duty engine. Fuel, 351, 128888. https://doi.org/10.1016/j.fuel.2023.128888

https://doi.org/10.1016/j.fuel.2023.1288...

; Lee et al., 2015Lee, S., & Kim, T. Y. (2015). Feasibility study of using wood pyrolysis oil-ethanol blended fuel with diesel pilot injection in a diesel engine. Fuel, 162, 65-73. https://doi.org/10.1016/j.fuel.2015.08.049

https://doi.org/10.1016/j.fuel.2015.08.0...

; Kim & Lee, 2015Kim, T. Y., Lee, S., & Kang, K. (2015). Performance and emission characteristics of a high-compression-ratio diesel engine fueled with wood pyrolysis oil-butanol blended fuels. Energy, 93, 2241-2250. https://doi.org/10.1016/j.energy.2015.10.119

https://doi.org/10.1016/j.energy.2015.10...

; Sakthivel et al., 2019Sakthivel, R., Ramesh, K., Marshal, S. J. J., & Sadasivuni, K. K. (2019). Prediction of performance and emission characteristics of diesel engine fuelled with waste biomass pyrolysis oil using response surface methodology. Renewable energy, 136, 91-103. https://doi.org/10.1016/j.renene.2018.12.109.

https://doi.org/10.1016/j.renene.2018.12...

; Yalçin & Mutlu, 2022Yalçin, A. H., & Mutlu, i. (2022). Atik Vigne Çekirdeg Pirolitik Yagin Dizel Motorlarda Alternatif Yakit Olarak Kullanilabilirligi. Afyon Kocatepe Üniversitesi Fen Ve Mühendislik Bilimleri Dergisi, 22(4), 963-971. https://doi.org/10.35414/akufemubid.1077035

https://doi.org/10.35414/akufemubid.1077...

). PO is a liquid produced through the pyrolysis process, which involves the decomposition and evaporation of organic material (like biomass) under oxygen-free, high temperature conditions (350°C-700°C), cooling, and condensing (A. Bridgwater, 2013Bridgwater, A. V. (2003). Renewable fuels and chemicals by thermal processing of biomass. Chemical engineering journal, 91(2-3), 87-102. https://doi.org/10.1016/S1385-8947(02)00142-0.

https://doi.org/10.1016/S1385-8947(02)00...

; Prakash et al., 2013Prakash, R., Singh, R. K., & Murugan, S. (2013). Use of biodiesel and bio-oil emulsions as an alternative fuel for direct injection diesel engine. Waste and Biomass Valorization, 4, 475-484. https://doi.org/10.1007/s12649-012-9182-y

https://doi.org/10.1007/s12649-012-9182-...

). Unlike hydrothermal liquefaction (HTL), which operates at high temperatures and pressures (250°C-350°C, 10-25 MPa) and is effective for wet biomass, pyrolysis can process a broader range of dry feedstocks with simpler equipment requirements (Gollakota et al., 2018Gollakota, A. R. K., Kishore, N., & Gu, S. (2018). A review on hydrothermal liquefaction of biomass. Renewable and Sustainable Energy Reviews, 81, 1378-1392. https://doi.org/10.1016/j.rser.2017.05.178.

https://doi.org/10.1016/j.rser.2017.05.1...

). Transesterification, on the other hand, specifically targets fats and oils to produce biodiesel using alcohol and catalysts, making it less versatile compared to pyrolysis (Ma & Hanna, 1999Ma, F., & Hanna, M. A. (1999). Biodiesel production: a review. Bioresource technology, 70(1), 1-15. https://doi.org/10.1016/S0960-8524(99)00025-5

https://doi.org/10.1016/S0960-8524(99)00...

). Supercritical fluid extraction uses supercritical fluids, such as CO2, to extract bio-oil with high purity, although a higher costs and complexity (Reverchon, 1997Reverchon, E. (1997). Supercritical fluid extraction and fractionation of essential oils and related products. The Journal of Supercritical Fluids, 10(1), 1-37. https://doi.org/10.1016/S0896-8446(97)00014-4

https://doi.org/10.1016/S0896-8446(97)00...

). Biochemical conversion methods use microorganisms or enzymes, generally offering a more sustainable approach but often with lower efficiency and slower processing compared to pyrolysis (Himmel et al., 2007Himmel, M. E., Ding, S. Y., Johnson, D. K., Adney, W. S., Nimlos, M. R., Brady, J. W., & Foust, T. D. (2007). Biomass recalcitrance: engineering plants and enzymes for biofuels production. science, 315(5813), 804-807. https://doi.org/10.1126/science.1137016.

https://doi.org/10.1126/science.1137016...

). Other vegetable oils can be used as alternative fuels in diesel engines, such as PO. Vegetable oils have an energy density like diesel fuel and have a high viscosity. This high viscosity can make it difficult for the fuel to atomize properly through the engine injectors. Vegetable oils generally produce lower carbon monoxide (CO) and carbon dioxide (CO2) emissions but may result in higher nitrogen oxides (NOx) emissions (Hellier et al., 2015Hellier, P., Ladommatos, N., & Yusaf, T. (2015). The influence of straight vegetable oil fatty acid composition on compression ignition combustion and emissions. Fuel, 143, 131-143. http://doi.org/10.1016/j.fuel.2014.11.021.

http://doi.org/10.1016/j.fuel.2014.11.02...

; Nury, A., Garzón et al., 2019Garzón, N. A. N., Oliveira, A. A., & Bazzo, E. (2019). An ignition delay correlation for compression ignition engines fueled with straight soybean oil and diesel oil blends. Fuel, 257, 116050. https://doi.org/10.1016/j.fuel.2019.116050.

https://doi.org/10.1016/j.fuel.2019.1160...

; Jaafar et al., 2018Jaafar, M. N. M., & Safiullah, S. (2018). Combustion characteristics of rice bran oil biodiesel in an oil burner. Jurnal Teknologi, 80(3). https://doi.org/10.11113/jt.v80.11612

https://doi.org/10.11113/jt.v80.11612...

). PO typically has lower energy density and high viscosity, which negatively impacts engine performance and fuel atomization.

PO tends to produce higher carbon and particulate emissions and can cause rapid wear of engine components (Bridgwater, 2003Bridgwater, A. V. (2003). Renewable fuels and chemicals by thermal processing of biomass. Chemical engineering journal, 91(2-3), 87-102. https://doi.org/10.1016/S1385-8947(02)00142-0.

https://doi.org/10.1016/S1385-8947(02)00...

).

PO's poor qualities, including its high kinematic viscosity, low cetane number, high pH, and high-water content, restrict its direct application in diesel powered engines (Kim et al., 2015Kim, T. Y., Lee, S., & Kang, K. (2015). Performance and emission characteristics of a high-compression-ratio diesel engine fueled with wood pyrolysis oil-butanol blended fuels. Energy, 93, 2241-2250. https://doi.org/10.1016/j.energy.2015.10.119

https://doi.org/10.1016/j.energy.2015.10...

; Kim & Lee, 2015Lee, S., & Kim, T. Y. (2015). Feasibility study of using wood pyrolysis oil-ethanol blended fuel with diesel pilot injection in a diesel engine. Fuel, 162, 65-73. https://doi.org/10.1016/j.fuel.2015.08.049

https://doi.org/10.1016/j.fuel.2015.08.0...

; Lee et al., 2019Lee, S., Kim, T., & Kang, K. (2014). Performance and emission characteristics of a diesel engine operated with wood pyrolysis oil. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 228(2), 180-189. https://doi.org/10.1177/0954407013502951

https://doi.org/10.1177/0954407013502951...

, 2020). Numerous reserach works have been performed to improve the inadequate properties of PO and tested it as a fuel in internal combustion engines (Alcala & Bridgwater, 2013Bridgwater, A. (2013). Fast pyrolysis of biomass for the production of liquids. In Biomass combustion science, technology and engineering (pp. 130-171). Woodhead Publishing. https://doi.org/10.1533/9780857097439.2.130

https://doi.org/10.1533/9780857097439.2....

; Chiaramonti et al., 2003Chiaramonti, D., Bonini, M., Fratini, E., Tondi, G., Gartner, K., Bridgwater, A. V., ... & Baglioni, P. (2003). Development of emulsions from biomass pyrolysis liquid and diesel and their use in engines-Part 1: emulsion production. Biomass and bioenergy, 25(1), 85-99. https://doi.org/10.1016/S0961-9534(02)00183-6

https://doi.org/10.1016/S0961-9534(02)00...

; Huang et al., 2012Huang, Y., Han, X., Shang, S., & Wang, L. (2012). Performance and emissions of a direct-injection diesel engine operating on emulsions of corn stalk bio-oil in diesel. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 226(8), 1119-1129. https://doi.org/10.1177/0954407012438295

https://doi.org/10.1177/0954407012438295...

; Ikura et al., 2003Ikura, M., Stanciulescu, M., & Hogan, E. (2003). Emulsification of pyrolysis derived bio-oil in diesel fuel. Biomass and bioenergy, 24(3), 221-232. https://doi.org/10.1016/S0961-9534(02)00131-9

https://doi.org/10.1016/S0961-9534(02)00...

; Jiang & Ellis, 2010Jiang, X., & Ellis, N. (2010). Upgrading bio-oil through emulsification with biodiesel: mixture production. Energy & Fuels, 24(2), 1358-1364. https://doi.org/10.1021/ef9010669

https://doi.org/10.1021/ef9010669...

; Lee et al., 2014Lee, S., Kim, T., & Kang, K. (2014). Performance and emission characteristics of a diesel engine operated with wood pyrolysis oil. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 228(2), 180-189. https://doi.org/10.1177/0954407013502951

https://doi.org/10.1177/0954407013502951...

; Lin et al., 2016Lin, B. J., Chen, W. H., Budzianowski, W. M., Hsieh, C. T., & Lin, P. H. (2016). Emulsification analysis of bio-oil and diesel under various combinations of emulsifiers. Applied energy, 178, 746-757. https://doi.org/10.1016/j.apenergy.2016.06.104

https://doi.org/10.1016/j.apenergy.2016....

; Lu et al., 2012Lu, Q., Zhang, Z. B., Liao, H. T., Yang, X. C., & Dong, C. Q. (2012). Lubrication properties of bio-oil and its emulsions with diesel oil. Energies, 5(3), 741-751. https://doi.org/10.3390/en5030741

https://doi.org/10.3390/en5030741...

; Han et al., 2022Han, J., Wang, Y., Somers, L. M. T., & van de Beld, B. (2022). Ignition and combustion characteristics of hydrotreated pyrolysis oil in a combustion research unit. Fuel, 316, 123419. https://doi.org/10.1016/j.fuel.2022.123419

https://doi.org/10.1016/j.fuel.2022.1234...

). Blending PO with traditional hydrocarbon fuels like diesel (D) to enhance fuel properties is recommended for the safe use of PO in diesel engines (Honnery et al., 2008Honnery, D., Ghojel, J., & Stamatov, V. (2008). Performance of a DI diesel engine fuelled by blends of diesel and kiln-produced pyroligneous tar. Biomass and Bioenergy, 32(4), 358-365. https://doi.org/10.1016/j.biombioe.2007.10.004

https://doi.org/10.1016/j.biombioe.2007....

; Murugan et al., 2009Murugan, S., Ramaswamy, M. C., & Nagarajan, G. (2009). Assessment of pyrolysis oil as an energy source for diesel engines. Fuel processing technology, 90(1), 67-74. https://doi.org/10.1016/j.fuproc.2008.07.017

https://doi.org/10.1016/j.fuproc.2008.07...

; Doğan et al., 2012Doğan, O., Çelik, M. B., & Özdalyan, B. (2012). The effect of tire derived fuel/diesel fuel blends utilization on diesel engine performance and emissions. Fuel, 95, 340-346. https://doi.org/10.1016/j.fuel.2011.12.033

https://doi.org/10.1016/j.fuel.2011.12.0...

; Volli et al., 2014Volli, V., Singh, R. K., & Murugan, S. (2014). The use of mustard cake pyrolytic oil blends as fuel in a diesel engine. Waste and Biomass Valorization, 5, 661-668. https://doi.org/10.1007/s12649-013-9270-7

https://doi.org/10.1007/s12649-013-9270-...

; Martínez et al., 2014Martínez, J. D., Ramos, Á., Armas, O., Murillo, R., & García, T. (2014). Potential for using a tire pyrolysis liquid-diesel fuel blend in a light duty engine under transient operation. Applied Energy, 130, 437-446. https://doi.org/10.1016/j.apenergy.2014.05.056

https://doi.org/10.1016/j.apenergy.2014....

; Karagöz, 2020Karagöz, M. (2020). Investigation of performance and emission characteristics of an CI engine fuelled with diesel-waste tire oil-butanol blends. Fuel, 282, 118-872. https://doi.org/10.1016/j.fuel.2020.118872

https://doi.org/10.1016/j.fuel.2020.1188...

).

Due to polarity and density differences, PO cannot form a stable mixture with conventional hydrocarbon fuels, and phase separation occurs in a short time (Alcala & Bridgwater, 2013Bridgwater, A. (2013). Fast pyrolysis of biomass for the production of liquids. In Biomass combustion science, technology and engineering (pp. 130-171). Woodhead Publishing. https://doi.org/10.1533/9780857097439.2.130

https://doi.org/10.1533/9780857097439.2....

; Lee & King, 2015Lee, S., & Kim, T. Y. (2015). Feasibility study of using wood pyrolysis oil-ethanol blended fuel with diesel pilot injection in a diesel engine. Fuel, 162, 65-73. https://doi.org/10.1016/j.fuel.2015.08.049

https://doi.org/10.1016/j.fuel.2015.08.0...

; Lee et al., 2019Lee, S., Kim, T., & Kang, K. (2014). Performance and emission characteristics of a diesel engine operated with wood pyrolysis oil. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 228(2), 180-189. https://doi.org/10.1177/0954407013502951

https://doi.org/10.1177/0954407013502951...

, Lee et al., 2020Lee, S., Woo, S. H., Kim, Y., Choi, Y., & Kang, K. (2020). Combustion and emission characteristics of a diesel-powered generator running with N-butanol/coffee ground pyrolysis oil/diesel blended fuel. Energy, 206, 118201. https://doi.org/10.1016/j.energy.2020.118201

https://doi.org/10.1016/j.energy.2020.11...

). Therefore, it is necessary to add chemical additives to blend PO homogeneously with conventional hydrocarbon fuels and use it successfully as fuel in engines. Stable and uniform mixes of diesel and PO can be created by adding n-butanol as organic solvent (Huang et al., 2012Huang, Y., Han, X., Shang, S., & Wang, L. (2012). Performance and emissions of a direct-injection diesel engine operating on emulsions of corn stalk bio-oil in diesel. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 226(8), 1119-1129. https://doi.org/10.1177/0954407012438295

https://doi.org/10.1177/0954407012438295...

; Han & Somers, 2021Han, J., & Somers, L. M. T. (2021). Comparative investigation of ignition behavior of butanol isomers using constant volume combustion chamber under diesel-engine like conditions. Fuel, 304, 121347. https://doi.org/10.1016/j.fuel.2021.121347

https://doi.org/10.1016/j.fuel.2021.1213...

). Since n-butanol has a kinematic viscosity value close to that of diesel, it can effectively reduce the viscosity of blended fuels (Lee et al., 2020Lee, S., Woo, S. H., Kim, Y., Choi, Y., & Kang, K. (2020). Combustion and emission characteristics of a diesel-powered generator running with N-butanol/coffee ground pyrolysis oil/diesel blended fuel. Energy, 206, 118201. https://doi.org/10.1016/j.energy.2020.118201

https://doi.org/10.1016/j.energy.2020.11...

). However, diesel, PO, n-butanol fuel mixtures do not meet the auto-ignition condition because PO and n-butanol have lower auto-ignition properties (Kim & Lee, 2015Kim, T. Y., Lee, S., & Kang, K. (2015). Performance and emission characteristics of a high-compression-ratio diesel engine fueled with wood pyrolysis oil-butanol blended fuels. Energy, 93, 2241-2250. https://doi.org/10.1016/j.energy.2015.10.119

https://doi.org/10.1016/j.energy.2015.10...

). Therefore, for stable combustion, cetane enhancers like 2-ethylhexyl nitrate (2-EHN) are required, which improve auto-ignition (Kim et al., 2015Kim, T. Y., Lee, S., & Kang, K. (2015). Performance and emission characteristics of a high-compression-ratio diesel engine fueled with wood pyrolysis oil-butanol blended fuels. Energy, 93, 2241-2250. https://doi.org/10.1016/j.energy.2015.10.119

https://doi.org/10.1016/j.energy.2015.10...

). In this research, PO was created using the biological waste process of pyrolysis using sour cherry kernels. Blended fuels consisting of PO, diesel, n-butanol and 2-EHN were examined in a diesel-powered engine with a single-cylinder and direct injection, and analysed with regards to combustion behaviour, exhaust emissions and engine performance.

2 MATERIALS AND METHODS

TEST FUELS

In this study, PO was obtained from a fast pyrolysis conversion process. PO did not mix with diesel due to unsatisfactory fuel properties. Accordingly, PO and diesel were mixed with n-butanol using a similar methodology as Alcala and Bridgwater (Alcala & Bridgwater, 2013Bridgwater, A. (2013). Fast pyrolysis of biomass for the production of liquids. In Biomass combustion science, technology and engineering (pp. 130-171). Woodhead Publishing. https://doi.org/10.1533/9780857097439.2.130

https://doi.org/10.1533/9780857097439.2....

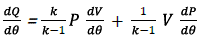

). To summarize, three-component mixtures were prepared at room temperature with different weight percentages (wt%) in bottles, maintaining a fixed total weight of 10 g. The bottles were closed, gently shaken, and allowed to rest for 48 hours at room temperature. Subsequently, the mixtures were visually examined for their homogeneity. All mixtures prepared as 5 wt% and their multiples were categorized as qualitatively immiscible (non-homogeneous) and miscible (homogeneous) according to a visual evaluation on the ternary phase diagram shown in Figure 1.

The presence of 35 wt% diesel in blended fuels indicates insufficient auto-ignition properties (Lee et al., 2020Lee, S., Woo, S. H., Kim, Y., Choi, Y., & Kang, K. (2020). Combustion and emission characteristics of a diesel-powered generator running with N-butanol/coffee ground pyrolysis oil/diesel blended fuel. Energy, 206, 118201. https://doi.org/10.1016/j.energy.2020.118201

https://doi.org/10.1016/j.energy.2020.11...

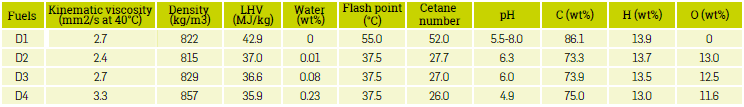

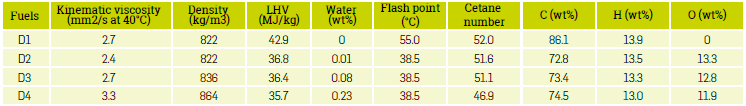

). Reducing the diesel content in blends is one of the study's objectives. To enhance auto-ignition, base fuel combinations with 40 wt% diesel and 60 wt% n-butanol, chosen from the small triangular zone displayed in the ternary phase diagram were selected. Subsequently, blended fuels with 5 wt% and 15 wt% PO were created by decreasing the n-butanol ratio and increasing the PO ratio in the base fuel. Measurements showed that the mixed fuels had lower cetane values than diesel due to their physicochemical properties. Consequently, the blended fuels were supplemented with 5 wt% 2-EHN to raise their cetane numbers. The fuel compositions and characteristics for diesel, n-butanol, 2-EHN, and PO are shown in Table 1. Diesel, n-butanol and 2-EHN were purchased separately from local suppliers, and their physicochemical properties were provided by the suppliers. Additionally, the physicochemical properties of PO and blended fuels were measured in a nationally accredited laboratory.

ENGINE TEST METHOD

The engine tests were conducted with a single-cylinder diesel powered engine operating at speeds of 1500,1800,2400,3000, and 3600 rpm, with a total engine load of 10 Nm. The specific features of the tested engine are given in Table 2.

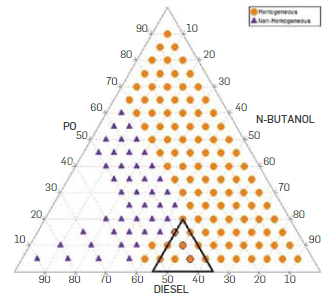

In the engine experiments, a direct current dynamometer (Kemsan) capable of producing 15 kW of power was used. Engine torque was measured with a torque measurement unit (Kistler 4550A). Using an encoder (Kistler 2614B), all angular movements of the crankshaft, top dead center, and engine speed measurements were detected precisely. Cylinder internal pressure was measured using a charge amplifier (Kistler 5064) and a high-sensitivity cylinder internal pressure sensor with a piezoelectric operating principle (A3 Kistler 6052C). A piezoresistive pressure sensor (Kistler 4065B) was used to detect the fuel line pressure. The KiBox data acquisition system manufactured by Kistler, was used to record fuel line pressure data, ncluding all signals produced for every 0.1-degree crank angle. The engine test setup is shown schematically in Figure 2.

Schematic of the engine test unit; 1. Engine, 2. Encoder, 3. Torque Meter, 4. Dynamometer, 5. Control Panel, 6. KiBox, 7. Computer, 8. Emission Gas Analyzer, 9. Smoke Meter, 10. Cylinder Pressure Sensor, 11. Fuel Line Pressure Sensor, 12. Electronic Scales

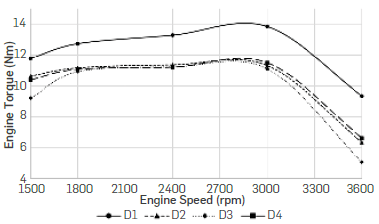

Using KiBox Cockpit software, the maximum cylinder pressure, cylinder position, the combustion's start and end angles, heat release rate, and maximum heat release rate of the test fuels were computed. The heat release rate was determined using the following equation:

Heat losses from the cylinder wall are not considered when calculating the heat release rate. In the equation, Q, 9, P, V, and k represent heat energy, cylinder pressure, cylinder volume, and the constant polytropic exponent (with k=1.37), respectively. Release of heat is represented by the start of combustion (SOC) and the end of combustion (EOC), which accounts for 5% and 90%, respectively. The duration of combustion (CD) is calculated as SOC minus EOC. The crank angle degree at which the injector rises to the opening pressure, which is set at 207 bar, is known as the start of injection (SOI). The time interval between SOI and SOC is referred to as the ignition delay (ID). Furthermore, for the emission measurements, an exhaust gas analyzer, Mobydick 5000 Kombi, was used

3 RESULTS AND DISCUSSION

COMPARISON OF FUEL PROPERTIES

At this stage, homogeneous fuel mixtures blended with PO, diesel, and n-butanol were selected to determine their physicochemical properties. Those mixtures with properties closer to diesel were chosen for engine testing. The properties of Dl, D2, D3 and D4 fuels are shown in Table 3. According to Table 3, the density and kinematic viscosity of fuels blended with 40 wt% diesel, 0-5-15 wt% PO, and 60-55-45 wt% n-butanol are close to conventional diesel fuel. The cetane numbers of the blended fuels range from 26 to 27.7. The European Union specifies a minimum cetane number of ≥51, while the United States sets it at ≥40 for diesel fuel (Lapuerta et al., 2009Lapuerta, M., Rodríguez-Fernández, J., & De Mora, E. F. (2009). Correlation for the estimation of the cetane number of biodiesel fuels and implications on the iodine number. Energy Policy, 37(11), 4337-4344. https://doi.org/10.1016/j.enpol.2009.05.049.

https://doi.org/10.1016/j.enpol.2009.05....

)

The cetane number decreased in the blended fuels as the PO content increased. A low cetane number is undesirable because it reduces the auto-ignitability of fuels, causes ID, delays SOC, and causes incomplete combustion (Hossain et al., 2016Hossain, A. K., Serrano, C., Brammer, J. B., Omran, A., Ahmed, F., Smith, D. I., & Davies, P. A. (2016). Combustion of fuel blends containing digestate pyrolysis oil in a multicylinder compression ignition engine. Fuel, 171, 18-28. https://doi.org/10.1016/j.fuel.2015.12.012

https://doi.org/10.1016/j.fuel.2015.12.0...

; Kaewbuddee et al., 2018Kaewbuddee, C., Wathakit, K., & Srisertpol, J. (2018, April). The effect of n-butanol to waste plastic oil fuel blends utilization on engine emissions of a single cylinder diesel engine. In 2018

IEEE International Conference on Applied System Invention (ICASI) (pp. 1224-1227). IEEE. https://doi.org/10.1109/ICASI.2018.8394510

https://doi.org/10.1109/ICASI.2018.83945...

; Prasad & Murugavelh, 2020Prasad, K. M., & Murugavelh, S. (2020). Experimental investigation and kinetics of tomato peel pyrolysis: Performance, combustion and emission characteristics of bio-oil blends in diesel engine. Journal of Cleaner Production, 254, 120115. https://doi.org/10.1016/j.jclepro.2020.120115

https://doi.org/10.1016/j.jclepro.2020.1...

). Hence, 5 wt% 2-EHN was added to the blends to increase the cetane number of the blended fuels (Lee et al., 2020Lee, S., Woo, S. H., Kim, Y., Choi, Y., & Kang, K. (2020). Combustion and emission characteristics of a diesel-powered generator running with N-butanol/coffee ground pyrolysis oil/diesel blended fuel. Energy, 206, 118201. https://doi.org/10.1016/j.energy.2020.118201

https://doi.org/10.1016/j.energy.2020.11...

). With the addition of 2-EHN, the cetane numbers of the tested blends increased to meet the minimum cetane number specification for diesel, ranging from 46.9 to 51.6, as shown in Table 4. Additionally, a one-degree increase in the flash points of the 2-EHN blended fuels was observed.

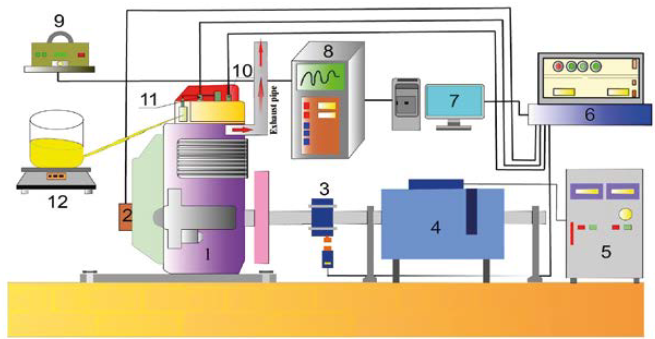

PERFORMANCE CHARACTERISTICS

The torque changes obtained in the engine experiments conducted with D1, D2, D3 and D4 fuels (with 2-EHN) in the 1500-3600 rpm engine speed range and under full load are shown in Figure 3. The maximum engine torque was achieved with D1 fuel between 24003000 rpm, averaging 13.57 Nm. The maximum engine torque values for blended fuels created with the addition of PO, n-butanol and 2-EHN, are very close to each other, averaging 11.28 Nm, and were obtained in the engine speed range of 2400-3000 rpm. In addition compared to Dl fuel, the engine torque decreased by an average of 16.83% in D2, D3 and D4 fuels in the 2400-3000 rpm range.

Engine torque change depending on engine speeds D1: Diesel 100% / PO 0% / NB 0% / 2-EHN 0%, D2: Diesel 40% / PO 0% / NB 55% / 2-EHN 5%, D3: Diesel 40% / PO 5% / NB 50% / 2-EH 5% and D4: Diesel 40% / PO 15% / NB 40% / 2-EHN 5%

Properties of test fuels (without 2-EHN) D1: Diesel 100% / PO 0% / NB 0%, D2: Diesel 40% / PO 0% / NB 60%, D3: Diesel 40% / PO5% / NB 55% and D4: Diesel 40% / PO 15% / NB 45%

Properties of fuels (with 2-EHN) D1: Diesel 100% / PO 0% / NB 0% / 2-EHN 0%, D2: Diesel 40% / PO 0% / NB 55% / 2-EHN 5%, D3: Diesel 40% / PO 5% / NB 50% / 2-EHN 5% and D4: Diesel 40% / PO 15% / NB 40% / 2-EHN 5%

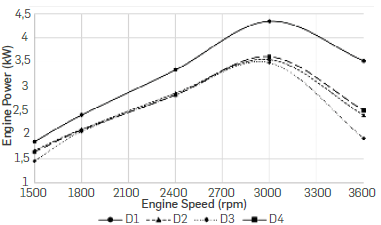

Engine power changes of the experimental studies conducted with D1, D2, D3 and D4 fuels (with 2-EHN) under full load in the 15003600 rpm engine speed range are shown in Figure 4. The maximum engine power of 4.35 kW was reached with D1 at 3000 rpm. The maximum engine powers for the blended fuels created with the addition of PO, n-butanol and 2-EHN, are very close to each other, averaging 3.55 kW at 3000 rpm. Engine power for D2, D3 and D4 fuels at 3000 rpm decreased by an average of 18.37% compared to D1 fuel.

Engine power change depending on engine speeds D1: Diesel 100% / PO 0% / NB 0% / 2-EHN 0%, D2: Diesel 40% / PO 0% / NB 55% / 2-EHN 5%, D3: Diesel 40% / PO 5% / NB 50% / 2-EHN 5% and D4: Diesel 40% / PO 15% / NB 40% / 2-EHN 5%

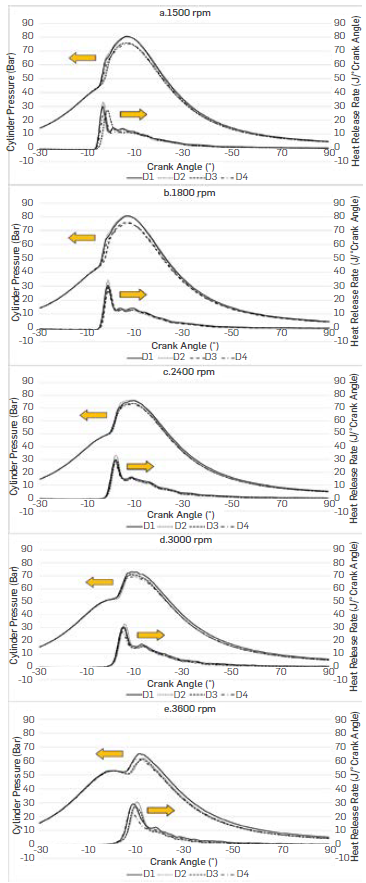

The changes in heat release rate and cylinder pressure of D1, D2, D3 and D4 test fuels at different engine speeds (1500-3600 rpm) and full load (10 Nm) related to crank angle are shown in Figure 5. The cylinder pressure peak of D3 and D4 fuels containing PO is lower at all engine speeds compared to D1 and D2 fuels. Notably, D2 fuel exhibits the highest cylinder pressure peak at 1500, 1800 and 2400 rpm. This is because D2 fuel contains a higher amount of n-butanol than other blended fuels. The combustion of D2 takes place is shorter as compared to other fuels, which comes from the higher oxygen amount of D2, thus improving the combustion process. When comparing D3 and D4 test fuels containing PO, the peak cylinder pressure decreases as the PO ratio increases at all engine speeds. This decrease is due to the lower oxygen content, reduced calorific value, increased kinematic viscosity and density, resulting from the increase of PO and the decrease of the n-butanol content in the blends. Additionally, under full load, the maximum cylinder pressures for all blended fuels decreases and reaches the minimum pressure value when the engine speed increases from low to high rpm. The increase in engine speed leads to longer ignition delay and shorter combustion time, which results in lower combustion temperature and reduced cylinder internal pressure due to decreased combustion quality. Among all test fuels, D2 exhibits the highest maximum heat release rate across all engine speeds, attributed to its higher n-butanol content. It is observed that the fuels with lower n-butanol content (D3 and D4) have lower maximum heat release rate values than the fuel with higher n-butanol content (D1). This is because increasing the PO ratio in the fuel mixtures reduces the oxygen content and LHV of the tested fuels, while increasing density and kinematic viscosity.

EMISSION CHARACTERISTICS

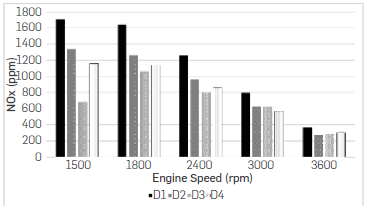

The characteristics of fuel mixtures' nitrogen oxide (NOx) emissions at varying engine speeds under full engine load are depicted in Figure 6. According to the findings, NOx emissions for PO, n-butanol and 2-EHN fuel mixtures are quite stable compared to D1. Additionally, NOx emissions for all fuels decrease as engine speed increases under full load.

Heat release rate and in-cylinder pressure changes of blended fuels D1: Diesel 100% / PO 0% / NB 0% / 2-EHN 0%, D2: Diesel 40% / PO 0% / NB 55% / 2-EHN 5%, D3: Diesel 40% / PO 5% / NB 50% / 2-EHN 5% and D4: Diesel 40% / PO 15% / NB 40% / 2-EHN 5%

NOx emissions of blended fuels at varying engine speeds D1: Diesel 100% / PO 0% / NB 0% / 2-EHN 0%, D2: Diesel 40% / PO 0% / NB 55% / 2-EHN 5%, D3: Diesel 40% / PO 5% / NB 50% / 2-EHN 5% and D4: Diesel 40% / PO 15% / NB 40% / 2-EHN 5%

Since the mixtures of PO, n-butanol and 2-EHN have lower calorific values, their heat release rates are lower and, therefore, the maximum cylinder pressure values are lower than D1. Consequently, the maximum in-cylinder temperatures occurring during combustion are also lower, leading to lower NOx emissions for these blends at all engine speeds compared to D1. Lower maximum temperatures, resulting from reduced maximum cylinder pressures, contribute to decreased NOx emissions (Emiroglu et al., 2018Emiroğlu, A. O., Keskin, A., & Şen, M. (2018). Experimental investigation of the effects of turkey rendering fat biodiesel on combustion, performance and exhaust emissions of a diesel engine. Fuel, 216, 266-273. https://doi.org/10.1016/j.fuel.2017.12.026

https://doi.org/10.1016/j.fuel.2017.12.0...

).

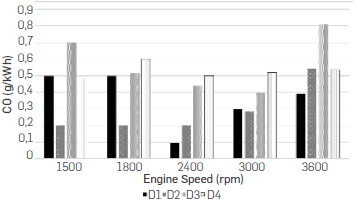

Figure 7 displays the carbon monoxide (CO) emission characteristics of blended fuels at varying engine speeds under full engine load. N-butanol addition, one of the alcohols with a high oxygen content, results in a decrease of CO because of the adequate oxygen amount and high combustion chamber temperature. Furthermore, carbon-to-hydrogen (C/H) ratio is lower in blends with alcohol compared to D1 fuel, which is another factor in their reduced CO emissions (De Caro, 2001De Caro, P. S., Mouloungui, Z., Vaitilingom, G., & Berge, J. C. (2001). Interest of combining an additive with diesel-ethanol blends for use in diesel engines. Fuel, 80(4), 565-574. https://doi.org/10.1016/S0016-2361(00)00117-4

https://doi.org/10.1016/S0016-2361(00)00...

; Swarna et al., 2022Swarna, S., Swamy, M. T., Divakara, T. R., Krishnamurthy, K. N., & Shashidhar, S. (2022). Experimental assessment of ternary fuel blends of diesel, hybrid biodiesel and alcohol in naturally aspirated CI engine. International Journal of Environmental Science and Technology, 19(9), 8523-8554. https://doi.org/10.1007/s13762-021-03586-7

https://doi.org/10.1007/s13762-021-03586...

; Yao et al., 2010Yao, M., Wang, H., Zheng, Z., & Yue, Y. (2010). Experimental study of n-butanol additive and multi-injection on HD diesel engine performance and emissions. Fuel, 89(9), 2191-2201. https://doi.org/10.1016/j.fuel.2010.04.008

https://doi.org/10.1016/j.fuel.2010.04.0...

). Since D2 fuel has the highest n-butanol content and lowest C/H ratio, it produces less CO than D1 at low engine speeds. D2 fuel produces less CO than D3 and D4 fuels at all engine speeds. It is observed that CO emissions increase because of higher PO and lower n-butanol ratios in fuels. This increases the viscosity and water content, leading to lower combustion temperature and impaired fuel atomization properties respectively (Keskin, 2017Keskin, A. (2017). Experimental investigation of the effect of cottonseed oil biodiesel eurodiesel mixtures on combustion, performance and emissions at full load. Afyon Kocatepe University Journal of Science and Engineering, 17, 797-809. https://doi.org/10.5578/fmbd.57621

https://doi.org/10.5578/fmbd.57621...

).

CO emissions of blended fuels at varying engine speeds D1: Diesel 100% / PO 0% / NB 0% / 2-EHN 0%, D2: Diesel 40% / PO 0% / NB 55% / 2-EHN 5%, D3: Diesel 40% / PO 5% / NB 50% / 2-EHN 5% and D4: Diesel 40% / PO 15% / NB 40% / 2-EHN 5%

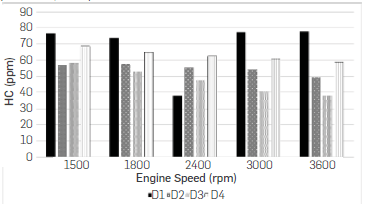

At full engine load and varying engine speeds, the tested fuels' hydrocarbon (HC) emissions are shown in Figure 8. Compared to D1, test fuels D2, D3 and D4 have lower HC emissions at all engine speeds. This reduction is attributed to the higher oxygen content in the fuel mixtures due to the presence of PO, n-butanol, and 2-EHN (Lee etat., 2020Lee, S., Woo, S. H., Kim, Y., Choi, Y., & Kang, K. (2020). Combustion and emission characteristics of a diesel-powered generator running with N-butanol/coffee ground pyrolysis oil/diesel blended fuel. Energy, 206, 118201. https://doi.org/10.1016/j.energy.2020.118201

https://doi.org/10.1016/j.energy.2020.11...

).

HC emissions of blended fuels at varying engine speeds D1: Diesel 100% / PO 0% / NB 0% / 2-EHN 0%, D2: Diesel 40% / PO 0% / NB 55% / 2-EHN 5%, D3: Diesel 40% / PO 5% / NB 50% / 2-EHN 5% and D4: Diesel 40% / PO 15% / NB 40% / 2-EHN 5%

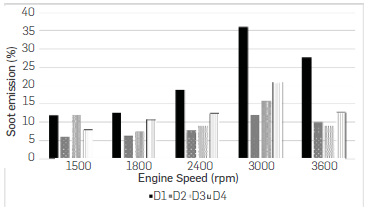

The test fuels' soot generation under full load and at varying engine speeds are shown in Figure 9. Our findings show that D2, D3 and D4 test fuels have lower soot (smoke density) emissions than D1 fuel under full engine load and at all engine speeds. Soot is caused by the incomplete combustion of carbon and hydrocarbon particles in the fuels. It is thought that the blended fuels containing PO, n-butanol and 2-EHN reduce soot emissions because they have a lower C/H ratio and higher oxygen content than D1 fuel. Among the test fuels, D2 fuel has the highest oxygen concentration and the lowest C/H ratio, resulting in the lowest soot formation. Conversely, D4 has the highest C/H ratio and the lowest oxygen concentration, leading to the highest soot formation. Therefore, as the PO ratio increases in the blended fuels, the oxygen content decreases, the C/H ratios increase, and soot emissions then increase.

Soot emissions of blended fuels at different engine speeds D1: Diesel 100% / PO 0% / NB 0% / 2-EHN 0%, D2: Diesel 40% / PO 0% / NB 55% / 2-EHN 5%, D3: Diesel 40% / PO 5% / NB 50% / 2-EHN 5% and D4: Diesel 40% / PO 15% / NB 40% / 2-EHN 5%

CONCLUSIONS

In this research work, the usability of PO, a fuel obtained from the pyrolysis of sour cherry kernels, was tested in a compression ignition engine. Blended fuels, designated as D1, D2, D3, and D4 were tested in an air-cooled single cylinder diesel engine under full load at engine speeds of 1500, 1800, 2400, 3000 and 3600 rpm. The results of our work lead to the following conclusions:

Maximum engine torque and power were achieved with D1 fuel. Compared to D1, engine torque, and power values for D2, D3, and D4 fuels were lower at all engine speeds. This reduction is attributed to the higher viscosity and lower LHV of the blended fuels.

The cylinder pressure peak of D3 and D4 fuels containing PO was lower at all engine speeds than D1 and D2 fuels. D2 exhibited the highest cylinder pressure, which is derived from the higher n-butanol content.

The maximum heat release rate was highest for D2 fuel across all engine speeds, which is attributed to its higher oxygen content from the n-butanol. The maximum heat release rate values of D3 and D4, which contain lower amounts of n-butanol due to PO addition, were lower than D1.

NOx emissions from D2, D3, and D4 fuels were remarkably lower than D1 at all engine speeds and full load. Additionally, NOx emissions from the blended fuels decreased with increasing engine speed.

Due to its higher n-butanol ratio and lower C/H ratio, D2 fuel produced less CO emissions at low engine speeds than D1, D3, and D4 fuels.

The HC emissions from D2, D3, and D4 fuels were lower than D1at all engine speeds. This reduction is likely due to the increased oxygen content from the addition of PO, n-butanol, and 2-EHN in fuel mixtures.

Soot emissions of D2, D3 and D4 blended fuels were lower at all engine speeds compared to D1 fuel. The amount of oxygen in blended fuels reduces as the PO ratio increases, leading to an increase in C/H ratios, and soot emissions.

Blended fuels of pyrolysis oil and diesel offer a promising path toward sustainability by reducing carbon footprints and enhancing energy security, while also providing economic benefits. However, challenges such as variable fuel quality, engine compatibility issues, and regulatory hurdles currently limit their widespread use. Advances in technology and infrastructure could help overcome these limitations, making blended fuels a more viable alternative in the future.

According to the results, we can consider that blends containing PO, diesel, n-butanol and 2-EHN are possible biofuels for diesel engine applications.

ACKNOWLEDGEMENTS

The Scientific Research Projects Coordination Unit at Afyon Kocatepe University provided funding for this study.

REFERENCES

- Alcala, A., & Bridgwater, A. V. (2013). Upgrading fast pyrolysis liquids: Blends of biodiesel and pyrolysis oil. Fuel, 109, 417-426. https://doi.org/10.1016/j.fuel.2013.02.058

» https://doi.org/10.1016/j.fuel.2013.02.058 - Barth, T., & Kleinert, M. (2008). Motor fuels from biomass pyrolysis. Chemical Engineering & Technology: Industrial Chemistry-Plant Equipment-Process Engineering-Biotechnology, 31(5),773-781. https://doi.org/10.1002/ceat.200800122

» https://doi.org/10.1002/ceat.200800122 - Bridgwater, A. V. (2003). Renewable fuels and chemicals by thermal processing of biomass. Chemical engineering journal, 91(2-3), 87-102. https://doi.org/10.1016/S1385-8947(02)00142-0

» https://doi.org/10.1016/S1385-8947(02)00142-0 - Bridgwater, A. (2013). Fast pyrolysis of biomass for the production of liquids. In Biomass combustion science, technology and engineering (pp. 130-171). Woodhead Publishing. https://doi.org/10.1533/9780857097439.2.130

» https://doi.org/10.1533/9780857097439.2.130 - Bridgwater, A. V., Meier, D., & Radlein, D. (1999). An overview of fast pyrolysis of biomass. Organic geochemistry, 30(12), 1479-1493. https://doi.org/10.1016/S0146-6380(99)00120-5

» https://doi.org/10.1016/S0146-6380(99)00120-5 - Bridgwater, A. V. (2012). Upgrading biomass fast pyrolysis liquids. Environmental Progress & Sustainable Energy, 31(2), 261-268. https://doi.org/https://doi.org/10.1002/ep.11635

» https://doi.org/https://doi.org/10.1002/ep.11635 - Chiaramonti, D., Bonini, M., Fratini, E., Tondi, G., Gartner, K., Bridgwater, A. V., ... & Baglioni, P. (2003). Development of emulsions from biomass pyrolysis liquid and diesel and their use in engines-Part 1: emulsion production. Biomass and bioenergy, 25(1), 85-99. https://doi.org/10.1016/S0961-9534(02)00183-6

» https://doi.org/10.1016/S0961-9534(02)00183-6 - Chong, K. J., & Bridgwater, A. V. (2017). Fast pyrolysis oil fuel blend for marine vessels. Environmental Progress & Sustainable Energy, 36(3), 677-684. https://doi.org/10.1002/ep.12402

» https://doi.org/10.1002/ep.12402 - De Caro, P. S., Mouloungui, Z., Vaitilingom, G., & Berge, J. C. (2001). Interest of combining an additive with diesel-ethanol blends for use in diesel engines. Fuel, 80(4), 565-574. https://doi.org/10.1016/S0016-2361(00)00117-4

» https://doi.org/10.1016/S0016-2361(00)00117-4 - Doğan, O., Çelik, M. B., & Özdalyan, B. (2012). The effect of tire derived fuel/diesel fuel blends utilization on diesel engine performance and emissions. Fuel, 95, 340-346. https://doi.org/10.1016/j.fuel.2011.12.033

» https://doi.org/10.1016/j.fuel.2011.12.033 - Emiroğlu, A. O., Keskin, A., & Şen, M. (2018). Experimental investigation of the effects of turkey rendering fat biodiesel on combustion, performance and exhaust emissions of a diesel engine. Fuel, 216, 266-273. https://doi.org/10.1016/j.fuel.2017.12.026

» https://doi.org/10.1016/j.fuel.2017.12.026 - Garzón, N. A. N., Oliveira, A. A., & Bazzo, E. (2019). Anignition delay correlation for compression ignition engines fueled with straight soybean oil and diesel oil blends. Fuel, 257, 116050. https://doi.org/10.1016/j.fuel.2019.116050

» https://doi.org/10.1016/j.fuel.2019.116050 - Gollakota, A. R. K., Kishore, N., & Gu, S. (2018). A review on hydrothermal liquefaction of biomass. Renewable and Sustainable Energy Reviews, 81, 1378-1392. https://doi.org/10.1016/j.rser.2017.05.178

» https://doi.org/10.1016/j.rser.2017.05.178 - Han, J., & Somers, L. M. T. (2021). Comparative investigation of ignition behavior of butanol isomers using constant volume combustion chamber under diesel-engine like conditions. Fuel, 304, 121347. https://doi.org/10.1016/j.fuel.2021.121347

» https://doi.org/10.1016/j.fuel.2021.121347 - Han, J., Somers, L. M. T., & van de Beld, B. (2023). Combustion and emission characteristics of hydrotreated pyrolysis oil on a heavy-duty engine. Fuel, 351, 128888. https://doi.org/10.1016/j.fuel.2023.128888

» https://doi.org/10.1016/j.fuel.2023.128888 - Han, J., Wang, Y., Somers, L. M. T., & van de Beld, B. (2022). Ignition and combustion characteristics of hydrotreated pyrolysis oil in a combustion research unit. Fuel, 316, 123419. https://doi.org/10.1016/j.fuel.2022.123419

» https://doi.org/10.1016/j.fuel.2022.123419 - Hellier, P., Ladommatos, N., & Yusaf, T. (2015). The influence of straight vegetable oil fatty acid composition on compression ignition combustion and emissions. Fuel, 143, 131-143. http://doi.org/10.1016/j.fuel.2014.11.021

» http://doi.org/10.1016/j.fuel.2014.11.021 - Himmel, M. E., Ding, S. Y., Johnson, D. K., Adney, W. S., Nimlos, M. R., Brady, J. W., & Foust, T. D. (2007). Biomass recalcitrance: engineering plants and enzymes for biofuels production. science, 315(5813), 804-807. https://doi.org/10.1126/science.1137016

» https://doi.org/10.1126/science.1137016 - Honnery, D., Ghojel, J., & Stamatov, V. (2008). Performance of a DI diesel engine fuelled by blends of diesel and kiln-produced pyroligneous tar. Biomass and Bioenergy, 32(4), 358-365. https://doi.org/10.1016/j.biombioe.2007.10.004

» https://doi.org/10.1016/j.biombioe.2007.10.004 - Hossain, A. K., Serrano, C., Brammer, J. B., Omran, A., Ahmed, F., Smith, D. I., & Davies, P. A. (2016). Combustion of fuel blends containing digestate pyrolysis oil in a multicylinder compression ignition engine. Fuel, 171, 18-28. https://doi.org/10.1016/j.fuel.2015.12.012

» https://doi.org/10.1016/j.fuel.2015.12.012 - Huang, Y., Han, X., Shang, S., & Wang, L. (2012). Performance and emissions of a direct-injection diesel engine operating on emulsions of corn stalk bio-oil in diesel. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 226(8), 1119-1129. https://doi.org/10.1177/0954407012438295

» https://doi.org/10.1177/0954407012438295 - Ikura, M., Stanciulescu, M., & Hogan, E. (2003). Emulsification of pyrolysis derived bio-oil in diesel fuel. Biomass and bioenergy, 24(3), 221-232. https://doi.org/10.1016/S0961-9534(02)00131-9

» https://doi.org/10.1016/S0961-9534(02)00131-9 - Jaafar, M. N. M., & Safiullah, S. (2018). Combustion characteristics of rice bran oil biodiesel in an oil burner. Jurnal Teknologi, 80(3). https://doi.org/10.11113/jt.v80.11612

» https://doi.org/10.11113/jt.v80.11612 - Jiang, X., & Ellis, N. (2010). Upgrading bio-oil through emulsification with biodiesel: mixture production. Energy & Fuels, 24(2), 1358-1364. https://doi.org/10.1021/ef9010669

» https://doi.org/10.1021/ef9010669 - Kaewbuddee, C., Wathakit, K., & Srisertpol, J. (2018, April). The effect of n-butanol to waste plastic oil fuel blends utilization on engine emissions of a single cylinder diesel engine. In 2018 IEEE International Conference on Applied System Invention (ICASI) (pp. 1224-1227). IEEE. https://doi.org/10.1109/ICASI.2018.8394510

» https://doi.org/10.1109/ICASI.2018.8394510 - Karagöz, M. (2020). Investigation of performance and emission characteristics of an CI engine fuelled with diesel-waste tire oil-butanol blends. Fuel, 282, 118-872. https://doi.org/10.1016/j.fuel.2020.118872

» https://doi.org/10.1016/j.fuel.2020.118872 - Keskin, A. (2017). Experimental investigation of the effect of cottonseed oil biodiesel eurodiesel mixtures on combustion, performance and emissions at full load. Afyon Kocatepe University Journal of Science and Engineering, 17, 797-809. https://doi.org/10.5578/fmbd.57621

» https://doi.org/10.5578/fmbd.57621 - Kim, T. Y., & Lee, S. H. (2015). Combustion and emission characteristics of wood pyrolysis oil-butanol blended fuels in a DI diesel engine. International Journal of Automotive Technology, 16, 903-912. https://doi.org/10.1007/s12239-015-0092-4

» https://doi.org/10.1007/s12239-015-0092-4 - Kim, T. Y., Lee, S., & Kang, K. (2015). Performance and emission characteristics of a high-compression-ratio diesel engine fueled with wood pyrolysis oil-butanol blended fuels. Energy, 93, 2241-2250. https://doi.org/10.1016/j.energy.2015.10.119

» https://doi.org/10.1016/j.energy.2015.10.119 - Lapuerta, M., Rodríguez-Fernández, J., & De Mora, E. F. (2009). Correlation for the estimation of the cetane number of biodiesel fuels and implications on the iodine number. Energy Policy, 37(11), 4337-4344. https://doi.org/10.1016/j.enpol.2009.05.049

» https://doi.org/10.1016/j.enpol.2009.05.049 - Lee, S., Kim, T. Y., & Kang, K. Y. (2015). A feasibility study of using pyrolysis oil/butanol blended fuel in a DI diesel engine (No. 2015-24-2437). SAE Technical Paper. https://doi.org/10.4271/2015-24-2437

» https://doi.org/10.4271/2015-24-2437 - Lee, S., Choi, Y., & Kang, K. (2019). Application of blended fuel containing coffee ground pyrolysis oil in a diesel generator. Fuel, 256, 115998. https://doi.org/10.1016/j.fuel.2019.115998

» https://doi.org/10.1016/j.fuel.2019.115998 - Lee, S., Kim, T., & Kang, K. (2014). Performance and emission characteristics of a diesel engine operated with wood pyrolysis oil. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, 228(2), 180-189. https://doi.org/10.1177/0954407013502951

» https://doi.org/10.1177/0954407013502951 - Lee, S., & Kim, T. Y. (2015). Feasibility study of using wood pyrolysis oil-ethanol blended fuel with diesel pilot injection in a diesel engine. Fuel, 162, 65-73. https://doi.org/10.1016/j.fuel.2015.08.049

» https://doi.org/10.1016/j.fuel.2015.08.049 - Lee, S., Woo, S. H., Kim, Y., Choi, Y., & Kang, K. (2020). Combustion and emission characteristics of a diesel-powered generator running with N-butanol/coffee ground pyrolysis oil/diesel blended fuel. Energy, 206, 118201. https://doi.org/10.1016/j.energy.2020.118201

» https://doi.org/10.1016/j.energy.2020.118201 - Lin, B. J., Chen, W. H., Budzianowski, W. M., Hsieh, C. T., & Lin, P. H. (2016). Emulsification analysis of bio-oil and diesel under various combinations of emulsifiers. Applied energy, 178, 746-757. https://doi.org/10.1016/j.apenergy.2016.06.104

» https://doi.org/10.1016/j.apenergy.2016.06.104 - Lu, Q., Zhang, Z. B., Liao, H. T., Yang, X. C., & Dong, C. Q. (2012). Lubrication properties of bio-oil and its emulsions with diesel oil. Energies, 5(3), 741-751. https://doi.org/10.3390/en5030741

» https://doi.org/10.3390/en5030741 - Ma, F., & Hanna, M. A. (1999). Biodiesel production: a review. Bioresource technology, 70(1), 1-15. https://doi.org/10.1016/S0960-8524(99)00025-5

» https://doi.org/10.1016/S0960-8524(99)00025-5 - Martínez, J. D., Ramos, Á., Armas, O., Murillo, R., & García, T. (2014). Potential for using a tire pyrolysis liquid-diesel fuel blend in a light duty engine under transient operation. Applied Energy, 130, 437-446. https://doi.org/10.1016/j.apenergy.2014.05.056

» https://doi.org/10.1016/j.apenergy.2014.05.056 - Murugan, S., Ramaswamy, M. C., & Nagarajan, G. (2009). Assessment of pyrolysis oil as an energy source for diesel engines. Fuel processing technology, 90(1), 67-74. https://doi.org/10.1016/j.fuproc.2008.07.017

» https://doi.org/10.1016/j.fuproc.2008.07.017 - Garzón, N. A. N., Oliveira, A. A., & Bazzo, E. (2019). An ignition delay correlation for compression ignition engines fueled with straight soybean oil and diesel oil blends. Fuel, 257, 116050. https://doi.org/10.1016/j.fuel.2019.116050

» https://doi.org/10.1016/j.fuel.2019.116050 - Prakash, R., Singh, R. K., & Murugan, S. (2013). Use of biodiesel and bio-oil emulsions as an alternative fuel for direct injection diesel engine. Waste and Biomass Valorization, 4, 475-484. https://doi.org/10.1007/s12649-012-9182-y

» https://doi.org/10.1007/s12649-012-9182-y - Prasad, K. M., & Murugavelh, S. (2020). Experimental investigation and kinetics of tomato peel pyrolysis: Performance, combustion and emission characteristics of bio-oil blends in diesel engine. Journal of Cleaner Production, 254, 120115. https://doi.org/10.1016/j.jclepro.2020.120115

» https://doi.org/10.1016/j.jclepro.2020.120115 - Reverchon, E. (1997). Supercritical fluid extraction and fractionation of essential oils and related products. The Journal of Supercritical Fluids, 10(1), 1-37. https://doi.org/10.1016/S0896-8446(97)00014-4

» https://doi.org/10.1016/S0896-8446(97)00014-4 - Sakthivel, R., Ramesh, K., Marshal, S. J. J., & Sadasivuni, K. K. (2019). Prediction of performance and emission characteristics of diesel engine fuelled with waste biomass pyrolysis oil using response surface methodology. Renewable energy, 136, 91-103. https://doi.org/10.1016/j.renene.2018.12.109

» https://doi.org/10.1016/j.renene.2018.12.109 - Swarna, S., Swamy, M. T., Divakara, T. R., Krishnamurthy, K. N., & Shashidhar, S. (2022). Experimental assessment of ternary fuel blends of diesel, hybrid biodiesel and alcohol in naturally aspirated CI engine. International Journal of Environmental Science and Technology, 19(9), 8523-8554. https://doi.org/10.1007/s13762-021-03586-7

» https://doi.org/10.1007/s13762-021-03586-7 - Volli, V., Singh, R. K., & Murugan, S. (2014). The use of mustard cake pyrolytic oil blends as fuel in a diesel engine. Waste and Biomass Valorization, 5, 661-668. https://doi.org/10.1007/s12649-013-9270-7

» https://doi.org/10.1007/s12649-013-9270-7 - Yalçin, A. H., & Mutlu, i. (2022). Atik Vigne Çekirdeg Pirolitik Yagin Dizel Motorlarda Alternatif Yakit Olarak Kullanilabilirligi. Afyon Kocatepe Üniversitesi Fen Ve Mühendislik Bilimleri Dergisi, 22(4), 963-971. https://doi.org/10.35414/akufemubid.1077035

» https://doi.org/10.35414/akufemubid.1077035 - Yao, M., Wang, H., Zheng, Z., & Yue, Y. (2010). Experimental study of n-butanol additive and multi-injection on HD diesel engine performance and emissions. Fuel, 89(9), 2191-2201. https://doi.org/10.1016/j.fuel.2010.04.008

» https://doi.org/10.1016/j.fuel.2010.04.008 - Zhang, Q., Chang, J., Wang, T., & Xu, Y. (2007). Review of biomass pyrolysis oil properties and upgrading research. Energy conversion and management, 48(1), 87-92. https://doi.org/10.1016/j.enconman.2006.05.010 , 25-31. https://doi.org/10.1111/gwmr.12349

» https://doi.org/10.1016/j.enconman.2006.05.010» https://doi.org/10.1111/gwmr.12349

AUTHORS

| Arif Hakan Yalçin |

Department of Transportation Services, Afyon Kocatepe University, Afyonkarahisar, Türkiye. ORCID: https://orcid.org/0000-0001-7661-5296 e-mail: ahyalcin@aku.edu.tr |

| İbrahim Mutlu |

Department of Automotive Engineering, Afyon Kocatepe University, Afyonkarahisar, Türkiye. ORCID: https://orcid.org/0000-0001-5563-1000 e-mail: ibrahimmutlu@aku.edu.tr |

| Ercan Şimşir |

Department of Automotive Engineering, Afyon Kocatepe University, Afyonkarahisar, Türkiye. ORCID: https://orcid.org/0000-0001-6655-2324 e-mail: esimsir@aku.edu.tr |

| Furkan Akbulut |

Department of Motor Vehicles and Transportation Technology, Hitit University, Çorum, Türkiye. ORCID: https://orcid.org/0000-0001-6826-7199 e-mail: furkanakbulut@hitit.edu.tr |

| Alaattin Osman Emiroğlu |

Department of Mechanical Engineering, Bolu Abant Izzet Baysal University, Bolu, Türkiye. ORCID: https://orcid.org/0000-0003-1880-2186 e-mail: aosmanemiroglu@ibu.edu.tr |

| Mehmet Şen |

Department of Motor Vehicles and Transportation Technology, Bolu Abant Izzet Baysal University, Bolu, Türkiye. ORCID: https://orcid.org/0000-0002-0769-0521 e-mail: sen_m@ibu.edu.tr |

| Ahmet Keskin |

Department of Motor Vehicles and Transportation Technology, Bolu Abant Izzet Baysal University, Bolu, Türkiye. ORCID: https://orcid.org/0000-0001-5306-0427 e-mail: keskin_a@ibu.edu.tr |

-

How to cite:

Yalçin et al., (2024). The impact of mixed fuels containing pyrolysis oil, diesel, n-butanol and 2-EHN on emissions and performance of diesel engine. Ciencia, Tecnología y Futuro - CT&F. Vol. 14(2), 59-66

Publication Dates

-

Date of issue

Jul-Dec 2024

History

-

Received

11 Jan 2024 -

Reviewed

31 Oct 2024 -

Accepted

15 Nov 2024