Experimental evaluation of the potential impacts of polymer breakthrough on topside operations at Yariguí-Cantagallo field conditions

Abstract

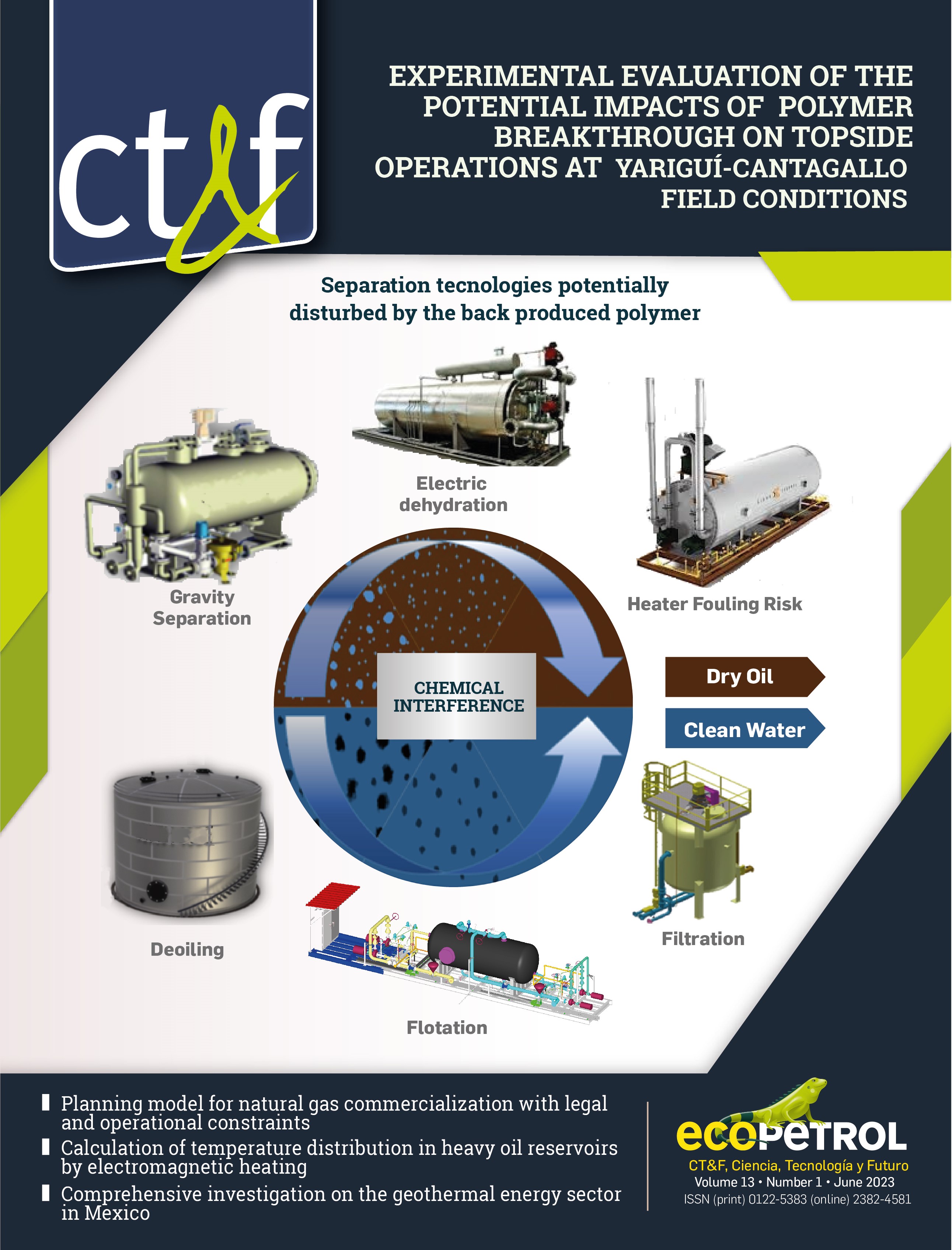

After a successful polymer injection pilot, Ecopetrol plans to deploy at full-field scale this enhanced oil recovery (EOR) technology on the Yariguí-Cantagallo field. Although a significant increase oil production is expected, the impact of the residual polymer on the produced water cycle should not be neglected. Indeed, after the polymer breakthrough, a significant part of the EOR chemical will be present in the produced fluids, and this may negatively impact the water/oil separation and the water treatment processes. An early review of this scenario provides an accurate vision of potential issues and, above all, enables to anticipate handling difficulties with produced fluids, and identifying mitigation strategies.

This paper proposes a specific and comprehensive experimental methodology to assess production risks using laboratory equipment designed to mimic the current separation processes of the Yariguí-Cantagallo field, which were as representative as possible. The objective is to highlight the impact of the residual polymer first on water/oil separation processes with bottle tests, electrostatic dehydration tests, and polymer fouling evaluation on heat exchangers and, second, on water treatment using long-term gravity separation tests, Jar test, flotation column, and walnut shell filtration unit. The assessment considered different scenarios in terms of polymer concentration, water-cut, water composition and initial oil content in the produced water. The compatibility between the polymer and some oilfield chemicals, such as demulsifiers and water clarifiers, was also investigated. The efficiency of these physical and chemical treatments was evaluated by monitoring the separation kinetics as well as by evaluating the quality of the phases with measures of water-in-oil content, oil-in-water content, or water turbidity.

For this case study and at laboratory scale, the polymer does not seem to stabilize tight emulsions, rather observing an improvement in water/oil separation kinetics. However, the quality of the separated water is strongly degraded with a higher oil content and some incompatibilities with current demulsifiers which reduce their efficiency have been observed. The risk of polymer precipitation or fouling on heat surface is very low under the experimental conditions tested. The performance of the different water treatment stages is slightly affected in the presence of polymer, even if the water quality remains good.

The operational risk assessment conclusions and pending recommendations draw the map of conditions where the residual polymer seems to cause problems or not. This anticipated experimental approach can provide clues and solutions to better manage the impact of the residual polymer in back produced fluids. Adjusting process parameters on existing surface facilities and working on chemical treatment optimization should ensure to produce oil, and release produced water on specifications. This challenge will be one of the keys for technical success and for upholding the expected economic performance of this EOR project.

References

al kalbani, A., Chandan, T., Kawthar, S., Ravula, C., Choudhuri, B., & Hashmi, K. (2014). Solvent stimulation to restore productivity of polymer pattern producer wells-a case study. In SPE EOR Conference at Oil and Gas West Asia. (pp. SPE-169714). SPE. https://doi.org/10.2118/169714-MS

Argillier, J.-F., Henaut, I., Darbouret, M., Jermann, C., & Vinay, G. (2018). Evaluation of EOR chemicals impact on topside operations. SPE EOR Conference at Oil and Gas West Asia. (p. D031S021R002). SPE. https://doi.org/10.2118/190438-MS

Argillier, J. F., Dalmazzone, C., Henaut, I., Mouazen, M., Noik, C., & Boufarguine, M. (2013). Methodological approach for analyzing the impact of chemical EOR on surface processes. SPE International Symposium on Oilfield Chemistry. (pp. SPE-164098). SPE. https://doi.org/10.2118/164098-MS

Beetge, J. H., & Horne, B. (2005). Chemical demulsifier development based on critical electric field measurements. SPE International Symposium on Oilfield Chemistry. (pp. SPE-93325). SPE. https://doi.org/10.2118/93325-MS

Cassar, C., Mouret, A., Salaün, M., & Klopffer, M.-H. (2021). Effect of Enhanced-Oil-Recovery Chemicals on Oil/Water-Separation Processes, from Laboratory Scale to Flow-Loop Scale. SPE Production & Operations, 36(01), 57-69. https://doi.org/10.2118/200455-PA

Chen, H.-x., Tang, H.-m., Duan, M., Liu, Y.-g., Liu, M., & Zhao, F. (2015). Oil–water separation property of polymer-contained wastewater from polymer-flooding oilfields in Bohai Bay, China. Environmental technology, 36(11), 1373-1380. https://doi.org/10.1080/09593330.2014.990522

Clemens, T., Deckers, M., Kornberger, M., Gumpenberger, T., & Zechner, M. (2013). Polymer solution injection–near wellbore dynamics and displacement efficiency, pilot test results, Matzen Field, Austria. EAGE Annual Conference & Exhibition incorporating SPE Europec. One Petro. https://doi.org/10.2118/164904-MS

Dalmazzone, C. (2017). The characterization of complex crude oil emulsions and foams? An essential step to mitigate separation issues. Chemistry in the oil industry 15th, Manchester, UK, 6-8. https://rscspecialitychemicals.org.uk/previous-conferences/chemistry-in-the-oil-industry-series/citoi-xv/

Dalmazzone, C., Noik, C., Glenat, P., & Dang, F. (2010). Development of a methodology for the optimization of dehydration of extraheavy-oil emulsions. SPE Journal, 15(03), 726-736. https://doi.org/10.2118/121669-PA

DeHekker, T., Bowzer, J., Coleman, R., & Bartos, W. (1986). A Progress Report on Polymer-Augmented Waterflooding in Wyoming's North Oregon Basin and Byron Fields. In SPE Improved Oil Recovery Conference? (pp. SPE-14953). SPE. https://doi.org/10.2118/14953-MS

Delamaide, E. (2021). Is chemical EOR finally coming of age? In IOR 2021, (Vol 2021 No 1. pp 1-30). European association of Geoscientists. https://doi.org/10.3997/2214-4609.202133010

Dhaliwal, A., Zhang, Y., Dandekar, A., Ning, S., Barnes, J., Edwards, R., . . . Ciferno, J. (2021). Experimental investigation of polymer-induced fouling of heater tubes in the first-ever polymer flood pilot on Alaska North Slope. SPE Production & Operations, 36(01), 70-82. https://doi.org/10.2118/200463-PA

Floerger, S. N. F. (2016). Recuperación Mejorada de Petróleo (EOR). Geología del petróleo-Sistemas petrolíferos EOR, 101(8). https://us.snf.com/wp-content/uploads/2017/03/EOR-101-Geolog%C3%ADa-del-petr%C3%B3leo-Sistemas-petrol%C3%ADferos.pdf.

Gbadamosi, A. O., Junin, R., Manan, M. A., Agi, A., & Yusuff, A. S. (2019). An overview of chemical enhanced oil recovery: recent advances and prospects. International Nano Letters, 9 171-202. https://doi.org/10.1007/s40089-019-0272-8

Graham, G. M., & Frigo, D. M. (2019). Production chemistry issues and solutions associated with chemical EOR. In SPE International Conference on Oilfield Chemistry. (p. D021S008R001). SPE. https://doi.org/10.2118/193568-MS

Jacob, M., Demangel, A., Goldszalu, A., Rambeau, O., Jouenne, S., & Cordelier, P. (2015). Impact of back produced polymer on tertiary water treatment performances. In SPE Asia Pacific Enhanced Oil Recovery Conference. (p. D021S011R003). SPE. https://doi.org/10.2118/174683-MS

Leitenmueller, V., Wenzina, J., Kadnar, R., Jamek, K., & Hofstaetter, H. (2017). Treatment of Produced Polymer-Containing Water with a Water Treatment Pilot Unit in the Matzen Field, Austria. Abu Dhabi International Petroleum Exhibition & Conference. (p. D021S044R005). SPE. https://doi.org/10.2118/188226-MS

Lu, Y., Kang, W., Jiang, J., Chen, J., Xu, D., Zhang, P., . . . Wu, H. (2017). Study on the stabilization mechanism of crude oil emulsion with an amphiphilic polymer using the β-cyclodextrin inclusion method. RSC advances, 7(14), 8156-8166. https://doi.org/10.1039/C6RA28528G

Manrique, E., Ahmadi, M., & Samani, S. (2017). Historical and recent observations in polymer floods: an update review. CT&F-Ciencia, Tecnología y Futuro, 6(5), 17-48. https://doi.org/10.29047/01225383.72

Mehta, N., Kapadia, G., & Panneer Selvam, V. (2016). Challenges in Full Field Polymer Injection Mangala in Field. SPE EOR Conference at Oil and Gas West Asia. (p. D021S015R001). SPE. https://doi.org/10.2118/179807-MS

Mittal, S., Anand, S., Venkat, P. S., Mathur, V., Zagitov, R., Subramanian, J., . . . Hammonds, P. (2018). Influence of EOR polymers on Fouling in Production Wells and Facilities. Abu Dhabi International Petroleum Exhibition and Conference. (p. D031S065R001) https://doi.org/10.2118/192943-MS

Mouret, A., Blazquez-Egea, C., Hénaut, I., Jermann, C., Salaün, M., Quintero, H., . . . Vargas, N. (2022). Screening of Topside Challenges Related to Polymer Presence in the Back Produced Fluids–Casabe Case Study. In SPE Improved Oil Recovery Conference? (p. D021S024R003). SPE. https://doi.org/10.2118/209419-MS

Opedal, M. T., Stenius, P., Johansson, L., & Hill, J. (2011). Mechanical Pulping: Flocculation of colloidal wood extractives in process water from precompression of chips in thermomechanical pulping. Nordic Pulp & Paper Research Journal, 26(1), 64-71. https://doi.org/10.3183/npprj-2011-26-01-p064-071

Rambeau, O., Alves, M.-H., Andreu, N., Loriau, M., & Passade-Boupat, N. (2016). Management of viscosity of the back produced viscosified water. In SPE EOR Conference at Oil and Gas West Asia. OnePetro. West Asia. https://doi.org/10.2118/179776-MS

Rowalt, R. (1973). A case history of polymer waterflooding brelum field unit. In SPE Annual Technical Conference and Exhibition? (pp. SPE-4671). SPE. https://doi.org/10.2118/4671-MS

Thakuria, C., Al-Amri, M. S., Al-Saqri, K. A., Jaspers, H. F., Al-Hashmi, K. H., & Zuhaimi, K. (2013). Performance review of polymer flooding in a major brown oil field of Sultanate of Oman. In SPE Asia Pacific Enhanced Oil Recovery Conference (pp. SPE-165262). SPE.. https://doi.org/10.2118/165262-MS

Thomas, A., Gaillard, N., & Favero, C. (2012). Some key features to consider when studying acrylamide-based polymers for chemical enhanced oil recovery. Oil & Gas Science and Technology–Revue d’IFP Energies nouvelles, 67(6), 887-902. https://doi.org/10.2516/ogst/2012065

Wylde, J. J., McMahon, J., & Mayner, S. (2011). S Scale Inhibitor Application in Northern Alberta-A Case History of an Ultra High Temperature Scale Inhibition Solution in Fire Tube Heater Treaters. In SPE International Conference on Oilfield Chemistry? (pp. SPE-141100). SPE. https://doi.org/10.2118/141100-MS

Zagitov, R., Mathur, V., Subramanian, J., & Selvam Venkat, P. (2020). Investigation on fouling during application of EOR polymer in Aishwarya field. In Abu Dhabi International Petroleum Exhibition and Conference (p. D012S116R159). SPE. https://doi.org/10.2118/203446-MS

Downloads

Copyright (c) 2023 CT&F - Ciencia, Tecnología y Futuro

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

| Article metrics | |

|---|---|

| Abstract views | |

| Galley vies | |

| PDF Views | |

| HTML views | |

| Other views | |